- Dassault Centre for Excellence,

- SAE Centre for Excellence in Surface Engineering,

- Robo 4.0 Lab.

- Friction Materials lab and library

These resources are specifically designed to facilitate both research activities and to teach UG and PG of students in the latest technological advancements.

The Department’s infrastructure includes

- UG & PG Class Rooms : 09 Nos

- Drawing Halls: 4 each seating capacity of 70.

- Air-conditioned Conference Hall: 100 sq.m

- Seminar hall with 120 seating capacity

- Department Library

- 12 printers and a photocopying machine with scanning facility

- 15 well equipped Laboratories of Total area of 3500 sq.m

- HOD office, faculty rooms and cubicles

- Around 200 Computers and 12 of Laptops

- 14 High-resolution LCD Projectors for lectures and seminars

- Internet facility with Wi-Fi connectivity

- The Faculty Rooms and All Laboratories are interconnected through 1Gbps LAN

LABORATORIES

The department has well equipped laboratories and workshops. The following are some of the important laboratories and workshops:

- Thermal lab

- Fluid mechanics and machinery lab

- Dynamics lab

- Material Testing and Metallurgy lab

- CAD lab

- CIM lab

- Metrology and Measurements lab

- Mechatronics lab

- Machine shop

- Engineering Practices lab

- Design Appreciation lab

- Surface Engineering lab

- Professional Welding lab

- Friction materials lab

- Robo lab 4.0

- Project lab

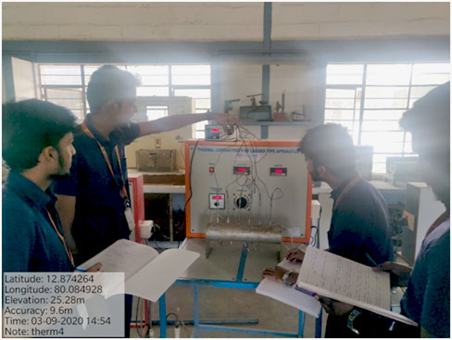

THERMAL LABORATORY

The lab has two divisions namely thermal engineering and heat & mass transfer for undergraduate students.

- This lab is equipped with Engine Testing Facility and different types of IC engines to measure various performance parameters of engines.

- Cut section models of four-stroke and two-stroke engines are available to facilitate understanding of valve and port openings.

- Different fuel testing equipment is available to measure calorific value, viscosity, flash point, fire point, pour point of any fuel.

- This lab is also intended for the students to understand the various modes of heat transfer principles.

| List of Major Equipment |

- Computerized Kirloskar Engine with Lab View based Engine Analyzer

- Multi-fuel Engine

- Sensors for Measurement of Speed, Load, Pressure, Crank Angle etc.

- Kane Automotive Exhaust Gas Analyser

- Single Cylinder Water Cooled Four Stroke Petrol Engine Eddy Current Dynamometer.

- Single Cylinder Air Cooled and Water Cooled Diesel Engines.

- Single Cylinder Air Cooled Four Stroke Petrol Start Kerosene Engine.

- Single Cylinder Four Stroke Water Cooled Diesel Engine.

- Single Cylinder Air Cooled Two Stroke Petrol Engine

- Multi – Cylinder Four Stroke Air Cooled Petrol Engine

- Twin Cylinder Water Cooled Diesel Engine.

|

- Vapour Compression Refrigeration Unit (R12) + (R134 a)

- Natural and Forced Convection Apparatus

- Double Pipe Heat Exchanger

- Shell and Tube Heat Exchanger

- Emissivity measurement Apparatus

- Stefan – Boltzmann Constant Apparatus

- Vapour Compression Air-Conditioning Test Rig (R12)

- Thermal Conductivity Measurement Apparatus (Liquid and Solid)

- Thermal conductivity Measurement Apparatus (Composite Plane Wall and Cylinder)

- Transient Heat Conduction Apparatus

- Boiling Heat Transfer Study Apparatus

|

FLUID MECHANICS AND MACHINERY LABORATORY

This lab is offered to the undergraduate students of different streams of engineering.

- The main purpose is to understand and demonstrate their knowledge gained from the fluid machineries.

- The laboratory consists of experiments related to flow measurements using different devices and related to losses in pipes.

- The performances and efficiency of various (Centrifugal, Gear, Jet, and Reciprocating) pump and various types of turbines (Peloton wheel turbine, Francis turbine, and Kaplan turbine) are also measured and demonstrated.

| List of Major Equipment |

- Friction Factor in Pipes

- Minor Losses in Pipe

- Venturi and Orifice Meter

- Jet Pump

- Vane Pump

- Gear Pump

- Centrifugal Pump (Single Speed)

- Francis Turbine

- Kaplan Turbine

- Submersible Pump

- Pelton Turbine

|

- “V” Notch

- Open Mouth piece

- Orifice

- Centrifugal Pump (Variable speed)

- Reciprocating Pump

- Impact of Jet on vanes

- Reynolds Apparatus

- Bernoulli’s Apparatus

- Rota Meter

- Metacentric Height

|

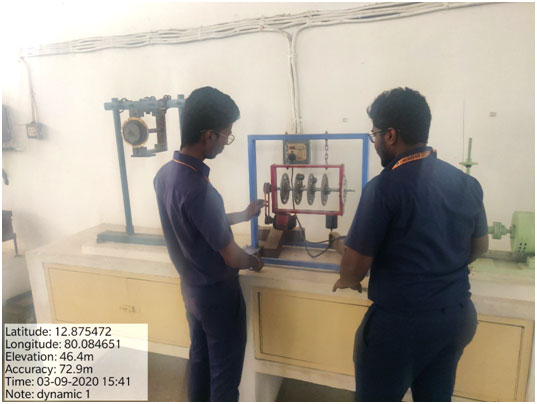

DYNAMICS LABORATORY

The objective of the lab is to understand the static force and dynamic force analysis and to study the undesirable effects of imbalances in rotors and engines.

The lab is also used to understand the concept of vibratory systems, their analysis, and the principles of control devices such as Governors and Gyroscopes.

| List of Major Equipment |

- Universal Governor Apparatus.

- Cam Analysis Machine.

- Motorised Gyroscope.

- Whirling Speed of Shaft Setup

- Dynamic Balancing Machine.

- Balancing of Rotating Masses Setup.

- Balancing of Reciprocating Masses Setup

|

- Longitudinal Vibration Setup

- Vibration Measuring Equipment’s – Uni-axial Shaker, Uni-axial & Tri-axial accelerometer, Impact Hammer and Data Acquisition System.

- Condenser Microphone

|

MATERIALS TESTING AND METALLURGY LABORATORY

The Material testing Laboratory offered for undergraduate students to understand the metallurgical analysis techniques.

- The lab is equipped with metallurgical microscopes, hardness tests for different ferrous and non-ferrous metals.

- This lab also used to measure the mechanical properties of ferrous and non-ferrous Metals by performing tensile and impact tests.

| List of Major Equipment |

- Metallurgical Microscope with Image Analyzer

- Salt Spray Chamber

- Electroless coating setup

- Non-ferrous melting furnace

- Double Disc Polishing Machine

|

- Heating furnace

- Belt Grinder

- Metallurgical Microscopes

- Specimen cut-off machine

- Specimen Molding Machine

|

CAD LABORATORY

CAD lab is offered to undergraduate and postgraduate students to get professional training on 2D & 3D engineering drawings using the latest version of software packages. Students also learn the structural analysis of various components. This lab consists of

Major Software

- Pro/e Creo 7.0 : University Plus (500 Seats)

- Ansys 2023 R2 (Academic) : 100 Seats

- (Research) : 10 Seats

- Matlab R 2013a : 100 Users

- AutoCAD Education Version : 30 User

CIM LABORATORY

The purpose of this lab is to familiarize the programming techniques in CNC part programming through Siemens NX Software Package. This lab is offered to both undergraduate as well as postgraduate-level students. The major Equipment are

- CNC Turning Center

- CNC Vertical Machining Center and

- 3D Printer

| List of Major Equipment |

- CNC Turning Centre Sprint 16 TC – 1 No

- CNC Vertical Machining Center- BMV 35 TC20- 1 No

- Seimens NX 12 CAD/CAM Software – 30 Seats

|

- Master CAM simulation Software – 1 Seat

- Desktop Computer – Dell & Acer – 35 Nos.

- 3D Printer- Olivetti S2 – 1 No

|

METROLOGY AND MEASUREMENTS LABORATORY

The Metrology lab houses instruments and tools to understand both experimental and theoretical measurements and determinations of uncertainty level in manufacturing products.

- The calibration exercises for the students make them find the standard error involved in the measuring instrument using a set of slip gauges.

- This lab extended its usage in the research for analyzing the surface roughness using a stylus and through image processing.

| List of Major Equipment |

- Coordinate Measuring Machine – TESA

- Surface Roughness Tester – TalySurf

- Precision XYZ Translation Stage – HOLMARC

- Vision System – National Instruments

- CCD Camera with Accessories – Basler

- CMOS Camera with Accessories – Basler

|

- Tool Maker’s Microscope – Mitutoy

- Autocollimator – Prisms India

- Surtronic – 10 Portable Surface Roughness Tester – TalySurf

- Profile Projector

- Other Conventional Instruments (Micrometer, Vernier, Gauges etc…)

|

The metrology lab is well equipped with surface roughness measuring devices through many research articles and funded projects are received.

Ongoing Project

| S.No |

Title of the Project |

Funding Agency |

Amount In INR (lakhs) |

Principle Investigator |

| 1. |

Non-contact Surface roughness measurement of Machined Surfaces using the Wavelet Metrics of laser Speckle images |

AICTE Research Promotion Scheme (RPS) (2020-2021) |

8.676 |

Dr. H. Siddhi Jailani, Professor/Mech Dr. J. Mashar Ali, Associate Professor/Mech |

Patents Published

| S.No |

Title of the Patent |

Status |

Inventors |

| 1. |

System and method for analysis of roughness quality of flat specimens using image processing |

Published |

Dr J. Mahashar Ali, Dr H. Siddhi Jailani and Dr M. Murugan |

Total no Ph.Ds completed – 02

| S.No |

Scholar Name |

Thesis Title |

Month and Year of Award |

| 1. |

Mr. T. Jeyapoovan |

characterization of machined surfaces using machine vision |

NOV 2013 |

| 2. |

Mr. J. Mahashar Ali |

Surface Roughness evaluation of machined surface using image processing |

JAN 2021 |

Papers Published

Few recently published papers.

| S.No |

Title of the Paper |

Authors |

Journal Name |

Month and Year |

DOI |

| 1 |

In-Situ Surface Roughness Evaluation of Surfaces Machined with EDM by Image Processing |

Dr J. Mahashar Ali, Dr H. Siddhi Jailani and Dr M. Murugan |

Journal of Non destructive Evaluation |

Aug 2022 |

https://doi.org/10.1007/s1 0921-022-00864-3 |

| 2 |

Surface roughness evaluation of electrical discharge machined surfaces using wavelet transform of speckle line images |

Dr J. Mahashar Ali, Dr H. Siddhi Jailani and Dr M. Murugan |

Measurement |

JAN 2020 |

https://doi.org/10.1016/j. Measurement.2019.10702 9,2020 |

MECHATRONICS LABORATORY

This lab imparts skill and knowledge on modular automation systems by implementing the automation skills achieved from the basics of PLC.

- This lab also consists of fluid power systems which contain basic pneumatic trainer kit, electro-pneumatic trainer kit, and hydraulic trainer kit.

| List of Major Equipment |

- GE Fanuc Programmable Logic Controller

- NI LabVIEW 8.2.1 and NI LabVIEW 2013

- NI 6009 – General Purpose DAQs 4 No

- NI 9213 – 16 channel Thermocouple DAQs 1 No

- NI 9237 – 4 channel strain DAQs 1 No

- NI Elvis II+ – Circuit Design Bundle – 1 No.

|

- cDAQ – Compact DAQ chassis – 5 Nos Festo pneumatic Trainer Kit

- Festo Pneumatics & Hydraulics simulation software.

- Agilent Digital Storage Oscilloscope with GPIB interface

- Pneumatic trainer kit.

- Kristler Accelerometer (Broad Band).

|

MACHINE SHOP

The Machine Shop provides knowledge on the various lathes , special machine tools and their attachments and various operations performed on them. The major machines tools and equipment available are:

| List of Major Equipment |

Lathe Shop

- Shimoga O’ bench lathe machine

- Ge Dee Weiler lathe machine

- Mahavir lathe machine

- Uday lathe machine

- Enterprise lathe machine

- Capstan lathe

- Automatic lathe machine

Special Machine Shop

- Electric Discharge Machining (EDM) Machine

- Horizontal Milling Machine

|

- Vertical Milling Machine

- Radial Drilling Machine

- Slotting Machine

- Gear Hobbing Machine

- Cylindrical Grinding Machine

- Surface Grinding Machine

- Shaping Machine

- Pillar Drilling Machine

- Power Hacksaw Machine

- Bench Grinding Machine

|

MANUFACTURING PRACTICE LABORATORY

This lab is offered as a central facility for all first-year undergraduate engineering students and is administered by the Department of Mechanical Engineering.

This manufacturing practice laboratory is equipped with bending machines, anvils, and welding machines to understand the principles and to fabricate various engineering components.

| List of Major Equipment |

- Smithy Furnace – 1 Nos

- Folding Machine – 1 Nos

- Shearing machine – 1 Nos

- Grinding Machine – 1 Nos

|

- Arc Welding Machine – 5 Nos

- Welding Booths – 3 Nos

- Gas Welding Set-up – 1 Nos

- Drilling Machine – 1 Nos

|

DESIGN APPRECIATION LABORATORY

The Design Appreciation Lab has products and subassemblies like Worm gearbox, pneumatic double acting cylinder, external gear pump, internal gear pump, centrifugal pump, rotary pump, and two-stage pump. These products are dismantled and re-assembled by the students. In this process, they learn the functioning of the product, materials used and tools with their specifications used for dismantling and assembly. This lab is offered for undergraduate mechanical engineers in the second semester itself.

| List of Major Equipment |

- Basic hand tools

- Basic power tools

- Standard machine components

- Work & tool holding devices

- Internal combustion (IC) engine

- IC engine components

- Fixed reduction gear box

|

- Blower

- Oil pumps

- Water pumps

- Reciprocating compressor

- Electric motor

- Electro-mechanical components

- Basic components for Toy design

|

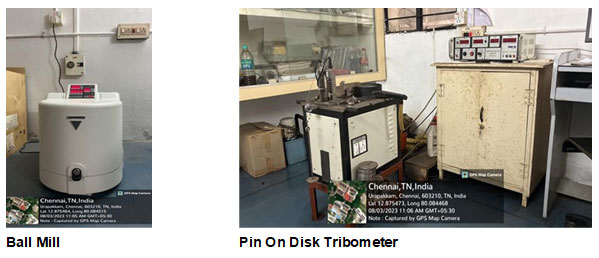

SURFACE ENGINEERING LABORATORY

The surface Engineering lab of the department is identified as the SAE Centre for excellence. The lab is equipped with Ducom Pin on disk tribo tester, ball mill and computerised microscopy and a high precision weighing scale. A number of project consultancy works are carried out. The lab witnesses one of the major research facility in which many research scholars, UG,PG scholars carry out their research work.

Recently completed projects

| S.No |

Title of the Project |

Funding Agency |

Amount In INR (lakhs) |

Principle Investigator |

| 1. |

Synthesis and characterization of ZrO2 Dispersed Ti, Ti-6Al-4V, Ti-6Al-5V, Ti-6Al-7Nb composite |

SERB-TARE (2018-2021) |

18.30 |

Dr. R. Karunanithi, Associate. Prof/Mech |

Total no Ph.Ds completed- 07

| S.No |

Scholar Name |

Thesis Title |

Month and Year of Award |

| 1. |

Mr. T.R. Tamilarasan |

Effect of Surfactants on The Characteristics of Electroless Composite Coatings |

MAY 2016 |

| 2. |

Mr. M. Pervez Ahmed |

Influence of cryogenic treatment on Cu-2 wt% Be Alloy |

AUG 2019 |

| 3. |

Mr. K. Sathickbasha |

Effect of Metal Fibers and Metal Sulfides Towrds Tribological Performance in NA Brake Pads |

JUL 2021 |

| 4. |

Mr. M. Abdur Rahman |

Effect of Aging and Ceramic Reinforcement on the Hardness and Wear Behavior of A1 7150 Alloy Composite by Powder Metallurgy |

AUG 2021 |

| 5. |

Mr. A. Prashanth |

Development of hybrid nano – AL2O3/Y2O3 dispersed AA 7017 by mechanical alloying followed by hot pressing process |

NOV 2021 |

| 6. |

Mr. A. Karthik |

Experimental investigation of AA2219-CeO2 composite Developed by Squeeze casting technique. |

JUL 2022 |

| 7. |

Mr. N. Ravikumar |

Investigation of Tribological Properties of Graphene Reinforced Friction Composite Tested on Modified Grey Cast Iron Disc |

SEP 2023 |

PROFESSIONAL WELDING LABORATORY (PWL)

The professional welding lab (PWL) equipped with modern welding equipment is established in March 2020 in association with FRONIUS India.

PWL is a facility or an entity that provides best practices, Hands-on training, technical support, Know-how about the latest trends and superior technology in the area of welding.

List of Major Equipment

1. Gas Tungsten Arc Welding (GTAW), 2. Gas Metal Arc Welding (GMAW), 3. Manual Metal Arc Welding (MMAW)

FRICTION MATERIALS LABORATORY

The friction materials Lab is established in November 2019.The lab is used to determine the wear rate of each brake pad at different brake disc speed and the applied force on the brake pad. It is used to evaluate the braking effectiveness of each brake pad in terms of stopping time.

Ongoing Projects

| S.No |

Title of the Project |

Funding Agency |

Amount In INR (lakhs) |

Principle Investigator |

| 1. |

rGo Coated steel fiber development for brake friction materials |

SERB-TARE (2022-2025) |

18.30 |

Dr. B Surya Rajan AP/Mech |

| 2. |

Fricteck Fibers (A faculty Startup mentored by CIIC and registered with startup India) |

Innovation Voucher Programme (IVP) –A Government of Tamil Nadu |

2.5 |

Dr. B Surya Rajan AP/Mech Dr. K. Sathickbasha AP/Mech Mr. P. Balaji Research Scholar/Mech |

Patents Published

| S.No |

Title of the Patent |

Status |

Inventors |

| 1. |

A friction material for brake and clutch lining and a method of preparation and thereof |

Published |

Dr. B Surya Rajan AP/Mech Dr. K. Sathickbasha AP/Mech Mr. P. Balaji Research Scholar/Mech |

Total no Ph.Ds completed- 03

| S.No |

Scholar Name |

Thesis Title |

Month and Year of Award |

| 1. |

Mr. B Surya Rajan |

Effects on Tribological performance of surface treated natural fiber and natural fillers in friction composites |

NOV 2020 |

| 2. |

Mr. Md Javeed Ahmed |

Characterization of Natural Fibers and their Influence on Physical Mechanical and Tribological Properties in Non Asbestos Organic Phenolic Friction Composites |

AUG 2021 |

| 3. |

Mr. K. Asrar Ahmed |

Evaluation of Tribological Performance of different types of Brass and its varying composition in disc brake pads |

AUG 2022 |

Papers Published

| S.No |

Title of the Paper |

Authors |

Journal Name |

Month and Year |

DOI |

| 1. |

The significance of low and high temperature solid lubricants for brake friction applications and their tribological investigation |

Mr P Balaji, Dr. B Surya Rajan, Dr K. Sathickbasha et al., |

Tribology International |

Mar 2024 |

https://doi.org/10.1016/

j.triboint.2023.109109 |

| 2. |

Effective utilization of high temperature sulfides in coated form on steel fibers for brake pad application and evaluating its tribological performance |

Dr. B Surya Rajan Mr. P. Balaji |

Tribology International |

Aug 2023 |

https://doi.org/10.1016/

j.triboint.2023.1088 69 |

| 3. |

Influence of metal sulfide coated steel fibers on the friction and wear performance of brake friction composite s |

Dr. B Surya Rajan, Dr K. Sathickbasha et al., |

Tribology International |

Sep 2022 |

https://doi.org/10.1016/

j.triboint.2022.1079

24 |

| 4. |

Synergistic effect of Bismuth III sulfide and Iron sulfide in the Tribological performance of brake friction composite |

Dr. B Surya Rajan, Dr K. Sathickbasha et al., |

Surface Topography: Metrology and properties |

May 2022 |

https://iopscience.iop.org/ article/10.1088/2 051-672X/ac6c41/meta (https://iopscience.iop.org/ article/10.1088/ 2051-672X/ac6c41/meta) |

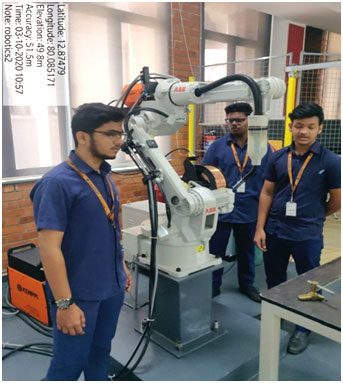

ROBOTICS LABORATORY

The Robotics lab is established in association with Pragrobotics Pvt. Ltd. Chennai. This lab also offers value added programmes in Artificial Intelligence, Machine learning and Robotics.

List of Major Equipment

1. Lean Arc Welder

Robot make : ABB Engineering Ltd

Robot type : IRB 1520ID

Handling capacity : 4 Kg

Reach : 1.5 m

Welding machine : KempArc SYN 500

Welding type : MIG

2. Computers

HP All-in-one PC : 40 Nos

3. Software

Robot Studio : 40 Licence

PROJECT LABORATORY

- The listed fabrication equipment’s provided with Drilling Machine, Angle Cutter, Hand Tools, and Power Tools (Drilling, Cutting, and Grinding).

- Final year and mini projects are carried out in the lab.

- Every year, the students participate in professional society events such as SAE INDIA where the vehicles are fabricated and tested in the project laboratory.

- Courses like MEC 2101 Manufacturing Processes, MEC 2211 Kinematics of Machinery are identified as project-based learning courses, where the students submit their fabricated projects utilizing the lab.

- The project laboratory is also open for the PG and Research scholars where the fabrication/experimental part of their research is carried out.

- Few project samples fabricated by the students for the courses and various SAE events.

Some of the

major equipment available are given below:

- CNC Turning Center

- CNC Vertical Machining Center

- Surface Roughness Tester

- Coordinate Measuring Machine

- Vision System

- AE with Digital Scope & GPIB interface

- Ultrasonic flaw detector

- Pin on Disc Wear Tester

- Salt Spray Corrosion Apparatus

- Vibration Sensors, shakers and DAQ

- Cryogenic Treatment Chamber

- Engine Testing Facility

- Engine Exhaust Emission Tester

- Electrical Discharge Machine

- Chase Testing Machine

- Olivetti S2 – 3D Printer

- MMAW Machine

- GTAW Machine

- GMAW Machine

- ABB Industrial (Welding) Robo.