DEPARTMENT OF MECHANICAL ENGINEERING

Mechanical

Advanced Testing & Consultancy Services

Overview

The Department of Mechanical Engineering offers consultancy and testing services to academic institutions, research organizations, and industries through its well-equipped laboratories. These facilities support material testing, mechanical characterization, vibration analysis, and other specialized measurements.

Guidelines to avail service

To avail the department’s consultancy services, please follow the steps below:

Form Submission

- Complete the Google Form: https://forms.gle/Cz7WcpR7B9pQMFkx8

- Select the appropriate laboratory and equipment as listed in the attached PDF.

- Provide the necessary user details and testing parameters.

Payment Details

- Refer to the attached PDF for consultancy charges.

- Make the payment through Net Banking / UPI / Challan to:

Account Name: Department of Mechanical Engineering

Account Number: 165702000000786

IFSC Code: IOBA0001657

Bank: Indian Overseas Bank, Vandalur

- Mention the laboratory name and equipment name in the payment remarks.

Approval and Confirmation

- After payment, submit the form and take a printout of the submission.

- Obtain the necessary approvals before commencing any test or consultancy activity.

Testing and Consultancy Service Charges

- The service charges for testing and consultancy are determined based on the type of equipment, nature of the test, and the complexity of analysis involved.

- Prospective users are requested to contact the department/ Lab in Charge to obtain a informal quotation prior to availing the services.

Laboratories & Facilities

1. CIM Laboratory

Technical Specification – Batliboi Sprint 16 TC

| Capacity | unit | Sprint 16 TC |

| Swing over bed | mm | 400 |

| Swing over carriage | mm | 250 |

| Distance between centres | mm | 380 |

| Maximum turning dia. | mm | 225 |

| Maximum turning length | mm | 325 |

| Main Spindle | ||

| Spindle nose | A2 – 5 | |

| Bore through spindle | mm | Dia. 40 |

| Maximum bar capacity | mm | Dia. 25 |

| Standard chuck size | mm | 165 |

| Front bearing bore/ rear bearing bore | mm | 70/60 |

| Spindle Drive | ||

| AC motor rated power (continuous rating / 30 min. rating) | Kw | 5.5/7.5 |

| Speed range (infinitely variable) | rpm | 40 – 4000 |

| Full power range | 1000 – 3000 | |

| Slides | ||

| z- axis stroke | mm | 325 |

| X – axis stroke | mm | 125 |

| Feed rate (infinitely variable) | Mm/min | 0 – 5000 |

| Rapid traverse rate – z axis | m/min | 32 |

| Rapid traverse rate – x axis | m/min | 32 |

| Slant angle | degree | 30 (to vertical) |

| Tail stock | ||

| Quill diameter | mm | 50 |

| Quill stroke | mm | 75 |

| Thrust adjustable | Kgf | 300 |

| Tail stock base travel | mm | 225 |

| Turret | ||

| No. of stations | 8 | |

| Maximum boring dia. | mm | Dia 25 |

| Tool cross section | mm | 20 x 20 |

| Control system | Siemens 802 D | |

| Accuracies (As per JIS std.) | ||

| Positioning accuracy x- axis | ±0.005 | |

| Positioning accuracy z- axis | ±0.0075 | |

| Repeatability x- axis | ± 0.002 | |

| Repeatability z- axis | ± 0.003 | |

| Installation data | ||

| Machine weight | Kg | 3000(Approx.) |

| Floor Space | mm | 3530 x 2575 (Approx.) |

| Total connecting load | KVA | 16 |

| Power supply | 3 Phase, 415V, 50 Hz |

Technical Specification – Bharat Fritz Werner BMV35 TC20

| Table | Unit | BMV35 TC20 |

| Clamping area | mm x mm | 600 x 350 |

| T-slots / width / centre distance | Nos. / mm / mm | 3 / 14 / 125 |

| Maximum safe load on table | Kg | 350 |

| Distance between table and spindle face | mm | 150 – 500 (300 – 700) |

| Traverse | ||

| X – axis | mm | 450 |

| Y – axis | mm | 350 |

| Z – axis | mm | 350 |

| Axis Drive | ||

| Feed rates | mm / min | 1 – 10000 |

| Rapid traverse X / Y / Z | m / min | 36 / 36 / 36 |

| Spindle | ||

| Power ( cont. / 15 min. rating) | kW | 3.7 / 5.5 (5.5 / 7.5) |

| Speed | rpm | 8000 (10000) |

| Taper | BT 40 | |

| Auto tool changer | ||

| Number of tools | Nos. | 20 |

| Max. tool dia. With adjacent pocket full / empty | mm | 80 / 125 |

| Maximum tool length | mm | 200 |

| Maximum tool weight | kg | 8 |

| Type of tool selection | Random | |

| Tool changing time | sec | 2.2 |

| Average chip-to-chip time | sec | 4.2 |

| Accuracy as per JIS | ||

| Positioning accuracy | mm | ± 0.005 |

| Repeatability | mm | ± 0.003 |

| Installation data | ||

| Electrical supply | 415 V AC, 3 Phase, 50 Hz | |

| Pneumatic supply as per ISO 8573 – 1 | Bar / lpm | 6 / 400 |

| Total connected load | kVA | 20 |

| Machine weight | kg | 3300 |

| CNC system | Fanuc 0i Mate |

Technical Specification – Olivetti S2 – 3D printer

| Table | Unit | BMV35 TC20 |

| Printing Area | mm x mm x mm | 400 x 400 x 400 |

| T-slots / width / centre distance | Nos. / mm / mm | 3 / 14 / 125 |

| Printing Technology | Fused Filament Fabrication (FFF) | |

| No. of Extruders | 2 | |

| Printing speed | mm / s | 150 |

| Nozzle diameter | mm | 0.30 to 0.80 |

| Printing volume approx. | liters | 64 |

| Minimum layer thickness | mm | 0.05 mm |

| Extruder maximum temperature | °C | 285 |

| Printing bed maximum temperature | °C | 120 |

| Filament diameter | mm | 1.75 |

| Dimensions | mm x mm x mm | 840 x 740 x 1210 |

| Weight | kg | 98 |

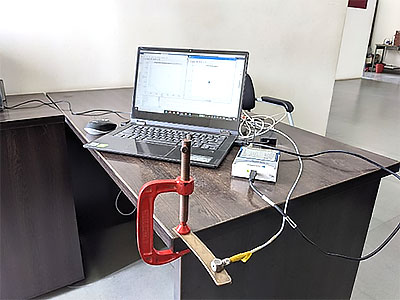

2. Dynamic Laboratory

|  |

Free Vibration | Modal analysis |

Technical Specification

| Instrument Name | Company | Specification |

| Uni-axial Accelerometer | KISTLER | Model: 8740A Range: 0 – 50 gSensitivity: 100 mV/g Frequency range: 7000 Hz Mounting type: M4.5 Threaded hole / Stud, Adhesive / Wax Temperature range: –54 – +75°C |

| Tri-axial Accelerometer | KISTLER | Model: 8763B Range: 0 – 50 g Sensitivity: 100 mV/g Frequency range: 7000 Hz Mounting type: M4.5 Threaded hole / Stud, Adhesive / Wax Temperature range: –54 – +100°C |

| Impact Hammer | KISTLER | Model: 9722A500 Measuring range: 0 – 500 N Frequency range: 8200 Hz Temperature range: –20 – +70°C |

| Data Acquisition System | National Instruments | Model: NI-9234 No. of Channels: 4Max Sampling Rate: 50ks/S ADC resolution: 24 bits |

| Uni-axial Shaker | Air cooled electro dynamic shaker Max Load: 100 KgfStroke: 25 mm Frequency Range: 20 to 20k Hz |

Technical Specification

| Instrument Name | Company | Specification |

| 146AE – ½” CCP Free field condenser microphone | GRAS | Freq Range:3.15 Hz to 20kHz Dynamic Range:18dB(A) to 133dB Sensitivity :50mV/pa Temperature: – 40 to 125c Humidity :10-90% IP 67 Rated |

Offered Testing and Consultancy Services

Vibration:

- Measurement of natural frequency of the sample material (free vibration – cantilever and free-free setup).

- Estimating logarithmic decrement of the sample material.

- Estimation of loss factor of the sample material.

- Modal analysis and Identification of Frequency Response Function (FRF) of the sample material.

Acoustics

- Sound Pressure Level (SPL) Measurement.

- Acoustic parameters such as reverberation time and clarity

- Frequency response function (FRF)

3. Thermal Engineering Laboratory

Technical Specifications

No. of cylinders: 1

No. of stroke: 4

Software: EngineSoft – Engine performance analysis software

Data acquisition device: NI USB-6210, 16-bit, 250 kS/s

Fuel: Diesel

Power: 3.5 kW

Speed: 1500 rpm

Compression ratio range: 12:1 – 18:1

Injection point Variation: 0 to 25° BTDC

Fuel: Petrol

Power: 4.5 kW

Speed: 1200 – 1800 rpm

Compression ratio range: 6:1 – 10:1

Injection point variation: 0 to 70° BTDC

Technical Specifications

| PARAMETER | RANGE | RESOLUTION | ACCURACY |

| Flue gas temperature | 0 – 600°C | 0.1°C | ±0.5°C |

| Oxygen, O2 | 0 – 25% | 0.1% | ±0.3% Volume |

| Carbon dioxide CO2 | 0 – 20% | 0.1% | ±0.3% Volume |

| Hydro carbon, HC | 0 – 2000 ppm | 1 ppm | ±5ppm < 100ppm 5% > 100ppm |

| Nitrogen Dioxide, NO2 | 0 – 1000 ppm | 1 ppm | ±5ppm < 100ppm 5% > 100ppm |

Technical Specifications

Heater control unit: 0-230 V, 0-2 A – single phase Dimmerstat

Ammeter: 0-2 A

Voltmeter: 0-200 V

Temperature Indicator: 0-200° C

4. Professional Welding Laboratory

Technical Specification

Make: Fronius India Limited

TIG (3 – 230 Amps),

MIG (10 – 220 Amps), and Manual Metal Arc (5 – 180 Amps)

5. Robo Laboratory

Technical Specification

Robot make : ABB Engineering Ltd

Robot M : IRB 1520ID

Handling capacity : 4 Kg

Reach : 1.5 m

Welding machine : KempArc SYN 500

Welding type : MIG

6. Metrology Laboratory

Technical Specification

Measuring range (x/y/z) : 460 x 510 x 420

Air pressure : 4.8 to 8.3 bar

Least count : 1 µm

Repeatability : 3 µm

Technical Specification

XY travel ranges : 50 X 50mm

Vertical working distance : 67mm

Least count : 0.005mm (Micro meter)

: 6” (Bevel protractor)

Eyepiece : 15x

Objectives : 2x and 10x

Technical Specification

Traveling length : 0 – 50mm

Resolution (Z) : 16nm @ 1mm

Stylus : Standard Diamond and 2µm radius

Software : form ultra

Technical Specification

Working Distance : 92mm and achieve 0.7µ per pixel

Field of View : High. 0.39 – Low. 2.5mm

Feature Size : High. 2.35 – Low. 7.25 µm

Internal coax LED : Red 627nm

Software : Pylon

7. Metallurgy Laboratory

Technical Specifications

| Max. temperature | -1850C |

| Capcity | 22 lts. |

| Cylinder capacity | (200+165) 365 lts. for 24 hrs test |

| Chamber dimensions | Diameter 25 cm and Depth 32 cm |

| Test conditions | Deep and Shallow test |

| Control | PLC controller |

| Purpose | All type metal and composite samples including Tensile samples, Small gears and Tool inserts |

Technical Specifications

| Belt Size | 100 X 915mm Endless Belt |

| Pulleys System | Balanced aluminium pulleys. |

| Motor power | 0.5 H.P Single Phase. |

| Working | 220V, Single phase |

| Purpose | Rough polish/remove of all metals for metallographic examination |

Technical Specification

| Magnification | 100X, 200X, 400X |

| Filters | Green and Red |

| Make | Chennai Metco |

| Image capture mechanism | Camera |

| Image analysis | Software |

| Purpose | Microstructural examination, Grain size estimation |

Technical Specifications

| Temperature | 10000C (max.) |

| Volume | 15*15*30 cm |

| Heating rate | 100C/min |

| Control | PID controller |

| Purpose | Heat treatment of all metals |

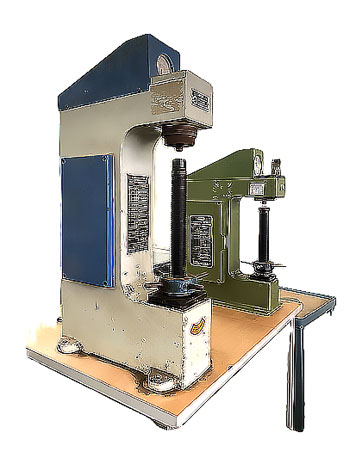

8. Material Testing Laboratory

Technical Specifications

| Type | Analog |

| Major load | 60,100,150 Kg |

| Purpose | Hardness measurements for all metals |

Technical Specifications

| Capacity | 200 kg.cm (max.) |

| Purpose | Fatigue test of welded samples and normal samples |

Technical Specifications

| Capacity | 1000 Kgs |

| Test | Tension and Compression |

9. Surface Engineering Laboratory

Technical Specifications

| Speed | 1000 rpm (Max.) |

| Load | 5 Kg (Max.) |

| Track Diameter | 95 mm (Max.) |

| Pin Diameter | 4, 6 and 10mm |

| Pin length | Min 20 mm |

| Condition | Dry and Wet |

| Purpose | Tribological studies of all materials |

Technical Specifications

| Speed | 650 rpm (Max.) |

| Grinding station | 1 |

| Jars | 500 ml |

| Balls and Jars | WC |

| Type | dry and wet grinding |

| Control | Storable SOPs and cycle programs |

| Purpose | Micro and Nano level metal powder production |

Technical Specifications

| Maximum speed | 1000 rpm |

| Stirrer | Magnetic and Magnetic with hot plate |

| Liquid Phase Controller | 1000C |

| Purpose | Electroless coating and Normal stirring |

10. Friction Materials Laboratory

Technical Specifications

| Electrical supply | 3 phase, 415V, 40Amps,50Hz with neutral and two independent earth (machine &control panel) |

| Air supply | Input -8 bar |

| Working pressure | Input-6 bar |

| Drum size | 277 mm (10.9″) to 280 mm (11.02″) inner diameter |

| Main spindle speed | 100 to 950rpm |

| Main Drive motor Motor Cooling Fan | AC motor variable speed motor,2pole, 15kW 8” cooling, 230VAC |

| Load on sample | 20 kgf (44 lb) to 125 kgf (275.6 lb) (Variable) |

| Load on Sample (pin on disk) | 20kgf |

| Heater | 6 .9kW (2.3kW x 3 nos.) |

| Cooling system | 1.1kw(1.5 hp) Centrifugal blower |

| Thickness measurement | Automatic by LVDT Max. 4mm |

| Sample size | 25x25x6mm |

| Load Measurement | 20-125kgf force |

| Friction Force Measurement | 0-200 kgf force |

| Temperature Measurement | “K” type button Thermocouple |

| Test Standard | IS2742 |

11. Machine Shop Laboratory

Technical Specifications

Make – Electranica

Work tank size – 500×300 mm

Longitudinal travel (X) – 280 mm

Transverse travel (Y) – 200mm

Quil travel (Z) -250 mm

Maximum permitted load on the tube – 175 kg

Over all dimensions – 1420×1140×2100 mm

Pulse generator: Maximum working current – 35+ 2AmpNo of power setting – 99×9Connected load – 3KVA

Power supply – 3phase, 415v Ac, 50Hz

Technical Specifications: PSG GH 600 / GH 200

| Maximum Module | 7 mm |

| Setting of Helical gear | Left side 45o Right side 45o |

| Maximum dia of gear | 600 mm |

| Maximum face width of gear | 260 mm |

| Max/ Min No. of teeth | 150/4 |

| Main drive motor | 2.2 KW |

Technical Specifications: Model BVR3

| Working Arm Length | 700 mm |

| Spindle Taper | MT 3 (Morse Taper 3) |

| Maximum Spindle Speed range | 56 to 2800 rpm |

| Maximum Drilling Capacity | 35 mm |

| Swing of Arm | 360o |

Technical Specifications: Batliboi, Model – FA3

| Working table Length & Width | 120 x 300 mm |

| Number of T slot | 3 |

| Range of power feeds: Longitudinal and cross | 14 – 900 mm/minutes |

| Number of spindle speeds | 12 mm |

| Spindle nose | ISO 40 |

| Range of spindle speed | 45 to 2000 rpm |

Technical Specifications: 5.5 Feet Lathe Machine Enterprise 1330 mm

| Maximum length of the turning | 1016 mm |

| Spindle bore | 44.5 mm |

| Number of the rotary speed of the spindle | 16 pcs |

| Minimum rotary speed of the spindle | 75 1/min |

| Maximum rotary speed of the spindle | 2000 1/min |

Technical Specifications: 225 mm classic Model

Horizontal Band Saw Bandsaw Machine Steel Master 225

Model: vm-225

Cutting capacity: 225 mm

Saw motor : 2 hp

Blade size : 3000×0.9×27

Weight : 360kg

Contact & Support

For queries or clarifications, please contact the Department of Mechanical Engineering or the respective laboratory in-charge (contact details are provided in the PDF – Testing and Consultancy Service Charges ).