|

| Designation | : | Assistant Professor (Sr. Gr.) |

| Nature of Employment | : | Regular |

| Qualification | : | B.E, M.S (By Research), PhD (Mechanical) |

| Phone | : | +91 44 2854 3110 (Home), +91 9445162696 (Mobile) |

| Email ID | : | mahashar@byt.digital/wordpress/crescent |

Teaching

Educational Background

| Degree | Discipline | Year of Passing | University |

|---|---|---|---|

| Ph.D | Mechanical Engineering | January 2021 | B S Abdur Rahman Crescent Institute of Science and Technology |

| M.S (By Research) |

Mechanical Engineering | 2009 | Anna University, Chennai |

| B. E | Production Engineering | 1999 | PSG College of Technology, Bharathiyar University, Coimbatore. |

Work Experience

| Designation | Institution | Duration | No. of Years |

|---|---|---|---|

| Lecturer Trainee | Crescent Engineering College | 10.11.1999 to 28.01.2002 | 2 |

| CAD Engineer | B.S.Abdur Rahman Crescent Engg. College | 28.01.2002 to 18.04.2005 | 3 |

| Lecturer to present Asst. Professor (Senior Grade) | B.S.Abdur Rahman Crescent Institute of Science and Technology | 18.04.2005 to till date | 15 |

Lecture courses

- Additive Manufacturing & Digital Manufacturing

- Basics of Mechanical Engineering

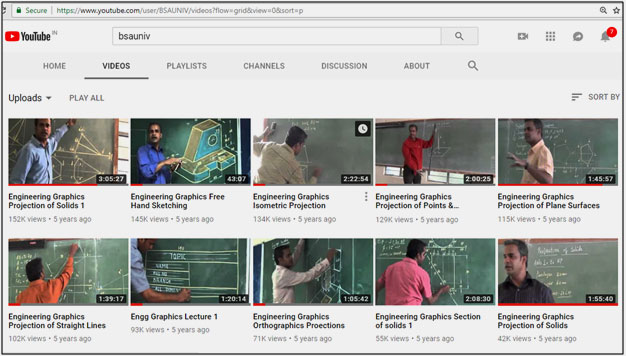

- Engineering Graphics (Delivered a whole you tube lecture in this subject)

- Engineering Mechanics (Partial you tube lectures delivered in this subject)

- Solid Mechanics

- Thermodynamics

- Manufacturing Technology

- Metrology and Mechanical Measurements

- Automobile Engineering

- Finite Element Method

Research

Areas of Research Interest

- Chip Form Monitoring in Metal Cutting (Metal Cutting)

- Surface Roughness Evaluation of Machined Surfaces using Image Processing (Measurement)

Publications

- Published 20 you tube video lectures on Engineering Graphics which is having a total of more than 13 lakh The lectures also well commented.

Youtube lecture Link: https://www.youtube.com/user/BSAUNIV/videos?sort=p&flow=grid&view=0 - Mohamed Fahad S, Mahashar Ali J and Siddhi Jailani H., (2021) “Characterization of surface roughness of ground specimens using image processing” Advances in Design and Thermal Systems, pp. 133-141.

- Ali, J. Mahashar, Siddhi Jailani and Murugan M, (2020). Optical surface roughness evaluation of ground specimens using speckle line images (No. 2020-28-0514). SAE Technical Paper.

- Ali, J. Mahashar, H, Siddhi jailani and M. Murugan. (2020) “Surface Roughness Evaluation of Electrical Discharge Machined Surfaces using Wavelet transform of Speckle Line images.” Measurement.

https://doi.org/10.1016/j.measurement.2019.107029 - Ali, J., Jailani, H. and Murugan, M., (2019). Surface Roughness Evaluation of Milled Steel Surfaces Using Wavelet Transform of Laser Speckle Line Images. Lasers in Engineering, Vol. 44, pp. 371-384.

- Ali, M., Jailani, S., Mariappan, M., Anandan, M. and Pavithran, V., (2019). Vision Based Surface Roughness Characterization of Flat Surfaces Machined with EDM (No. 2019-28-0148). SAE Technical Paper.

- Ali, J. Mahashar, H. Siddhi Jailani, and M. Murugan. (2019) “Surface Roughness Evaluation of Milled Surfaces by Image Processing of Speckle and White-Light Images.” Advances in Manufacturing Processes, pp. 141-151.

- Suhail, SI Mohamed, Mahashar Ali, H. Siddhi Jailani, and M. Murugan.(2018) “Vision based system for surface roughness characterisation of milled surfaces using speckle line images.” IOP Conference Series: Materials Science and Engineering, vol. 402, no. 1, p. 012054.

- Ali, J. Mahashar, and M. Murugan. (2017) “Surface roughness characterisation of turned surfaces using image processing.” International Journal of Machining and Machinability of Materials 19, no. 4: 394-406.

- Mahashar Ali J. and Murugan M., (2009) “Influence of Chip Breaker Location and Angle on Chip Form in Turning Low Carbon Steel”, Journal of Machining and Machinability of Materials, Vol. 5, No. 4, pp. 452-475.

- Google scholar Citations: 56

- H- index: 5

- i10- index: 5

International & National Journal

- Mahashar Ali J. and Murugan M., ‘Influence of Chip Breaker Location and Angle on Chip Form in Turning Low Carbon Steel’, Int. Journal of Machining and Machinability of Materials, 2009, Vol. 5, No. 4, pp. 452-475.

- Completed a course in “CNC Milling programming and operations” sponsored by B.S.A Crescent Engineering College at NSIC, Chennai from 30.11.2009 to 11.12.2009.

- Attended the “Educators Day 2009” the annual technical forum for faculty and research scholars conducted by National Instruments.

- Attended the national conference “APDMM 2008”, organized by Mechanical Engg. Department of BSA Crescent Eng. College during Jan 7- 8, 2008.

- Attended the seminar on “Heat Load Calculations” organized by Mechanical Engg. Department, Anna University, Chennai in association with ISHRAE Chennai Chapter (August 2008).

Patent Published

- Mahashar Ali, H. Siddhi Jailani and M. Murugan “System and method for analysis of roughness quality of flat specimens using image processing”. Application no. 201941019465 dated 16.05.2019 and published on 20.11.2020.

Extension

Additional Responsibilities:

- CAD Engineer (Having 5 years of experience in all CAD software)

- Incharge – Metrology Laboratory

- Various administrative positions