M.Tech. CAD-CAM

M.Tech. CAD-CAM

Eligibility

Fee Structure

Program Details

Eligibility

For NRI / Foreign National Candidates

B.E. / B.Tech. in Mechanical / Automobile / Manufacturing / Production / Industrial / Mechatronics / Metallurgy / Aerospace / Aeronautical / Material Science / Polymer / Plastics / Marine Engineering or Equivalent degree in relevant field with a minimum CGPA of 5.0 / 50% of marks.

- English as one of the subjects of qualifying examination

Fee Structure

Admission 2025-26

Tuition fee can be paid in two instalments in a year (semesterwise)

| Programme | Tuition Fee per Year (USD) | Amenities and Service Fee (USD) (One-time) |

|---|---|---|

| M. Tech. CAD-CAM (2 years) | 3000 | 500 |

Program Details

Admission Brochure

Programme Educational Objectives:

- To provide a holistic approach in learning through well designed courses involving fundamental concepts and state-of-the-art techniques in the field of CAD – CAM

- To equip the graduates, with knowledge and skill to undertake design, analysis, evaluation of systems, processes and components

- To supplement course work through seminars, workshops, case studies, value added programmesand through paper presentation

- To inculcate research culture by way of solving typical problems, Project works from real life situation and innovative assignments

- To develop team spirit, problem solving skill and appreciation for ethical and social relevance of the technologies used

Programme Outcomes:

Graduates will be able to

- Apply the knowledge of mechanical engineering fundamentals, and specialization in CAD-CAM to solve complex engineering problems

- Identify, formulate, review literature, and analyze complex engineering problems to arrive at substantiated conclusions using principles of mathematics and mechanical engineering sciences

- Design solutions for engineering problems and design system components or processes that meet the specified needs with appropriate consideration for the public health & safety, society, culture and environment

- Use research based knowledge and research methods including design of experiments, analysis and interpretation of data and synthesis of the information to provide valid conclusions

- Create, select, and apply appropriate techniques, resources, and modern engineering tools including prediction and modelling to engineering activities with an understanding of the limitations

- Apply reasoning informed by the contextual knowledge to assess societal, health, safety, legal and cultural issues and the consequent responsibilities relevant to the professional engineering practice

- Understand the impact of the professional engineering solutions in societal and environmental contexts, and demonstrate the knowledge of, and need for sustainable development

- Apply ethical principles and commit to professional ethics and responsibilities and norms of the engineering practice

- Function effectively as an individual, and as a member or leader in diverse teams, and in multidisciplinary settings

- Communicate effectively on complex engineering activities with the engineering community and with society at large, such as, being able to comprehend and write effective reports and design documentation, make effective presentations, and give and receive clear instructions

- Demonstrate knowledge and understanding of the engineering and management principles and apply these to one’s own work to manage projects

- Recognize the need for, and have the preparation and ability to engage in independent and life-long learning in the broadest context of technological change

Programme Specific Outcomes:

Graduates will be able to

- Design, analyse and manufacture real life components and systems using latest software in the field of computer aided design and computer aided manufacturing

- Undertake academic and research role to address open ended problems with conceptual knowledge and computational skill in the area of design and manufacturing

Click here for Detailed Syllabus

Salient Features

- Highly Qualified Faculty Members

- Accredited By National Board Of Accreditation (2016- 2018)

- Updated Curriculum With Emerging Trends In Technology As Courses (For eg.) IOT For Manufacturing

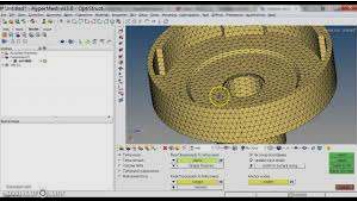

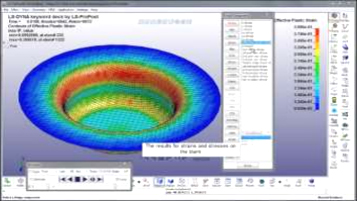

- World Class CAD/CAM Laboratories

- Outstanding Placements & Internships

- Experiencing The Usage of Modelling And Analysis Software Tools

- Network of 150+ Well Placed CAD-CAM Alumni

- Focus On Research, Innovation and Incubation

- National and International Collaborations for Research

- Innovation Centre

- Entrepreneurship and Incubation Cell

- Centrally Located Hi-Tech Campus

- Safe & Secure Campus

Lab Facilities

- CAD Lab

- CIM Lab

- Metrology Lab

Major – CAD Lab Software

PTC CREO 5.0 (500 Users) |

ANSYS V18 (Research 10 Users) (Teaching 100 Users) |

PTC CREO 5.0 (500 Users) |  ANSYS V18 (Research 10 Users) (Teaching 100 Users) |

MATLAB V8 R2013A (100 Users) |  LAB VIEW (100 Users) |

Major – CIM Lab Machines & Software

CNC Turning Center |

CNC Vertical Machining Center |

3D Printer |

Siemens NX 12.0 (30 Users) |

Major – Metrology Lab Equipement

Coordinate Measuring Machine |

Surface Roughness Tester |

Vision System |

Acoustic Emission Sensor with Digital Oscilloscope |

Vibration Sensors, Shakers and DAQ |

Tool Makers Microscope |

Image Acquisition setup with CCD / CMOS Camera | |

Recruiting Companies

- Vestas

- Fisher

- Renault Nissan

- IP Rings Limited

- Maruti-Suzuki

- Ashok Leyland

- Wabco

- Ford

- TCS

Noted Alumini’s

| Albert Einstein, Founder & CEO, EinNel Technologies |

| Karthikeyan Balaraman, Member of Technical Staff, Applied Materials, Inc. |

| Arun Venkatesh, Head BIM, L&T Constructions |

| Aswin Kumar, Manager, Technical at Optimuz Tech Services |

| J Shanmugasundaram, Senior Manager, DriveLine PD, Nissan Ashok Leyland Technologies |