Crescent Sustainability Initiatives

CLEAN WATER AND SANITATION (SDG 6)

INTEGRATED WATER CONSERVATION STRATEGY

B.S. Abdur Rahman Crescent Institute of Science and Technology has pioneered a comprehensive water-conscious building standard that represents a holistic approach to sustainable infrastructure management. The institute’s strategy goes beyond traditional water conservation methods, integrating advanced technological solutions, regulatory compliance, and innovative management practices. By implementing a multi-dimensional approach, the campus has transformed water management from a mere utility concern to a strategic environmental initiative, addressing critical challenges of water scarcity and resource optimization.

TECHNOLOGICAL INNOVATIONS AND INFRASTRUCTURE SOLUTIONS

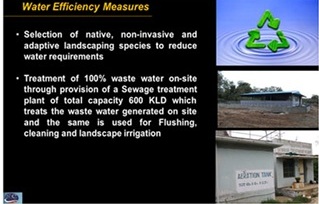

The water management infrastructure encompasses cutting-edge technologies and systematic interventions. A sophisticated rainwater harvesting system captures and stores precipitation, complemented by advanced sewage treatment plants that recycle water for non-potable applications like gardening and toilet flushing. Smart water management technologies, including IoT-based monitoring systems and digital flow meters, enable real-time tracking and optimization of water consumption. Specialized water-efficient fixtures such as low-flow showerheads, sensor-based taps, and dual-flush water closets further reduce overall water usage, demonstrating the institute’s commitment to technological innovation in resource conservation.

REGULATORY COMPLIANCE AND ENVIRONMENTAL STANDARDS

Adhering to national and international water conservation guidelines, the institute has developed a robust framework that meets stringent environmental standards. The water management approach aligns with the Ministry of Jal Shakthi guidelines (https://jalshakti-dowr.gov.in/guidelines/), groundwater extraction regulations, and comprehensive water conservation protocols. By implementing systematic water distribution management, including precise monitoring of raw water intake and advanced purification processes, the campus ensures optimal resource utilization while maintaining the highest quality standards for water consumption and recycling.

STAKEHOLDER ENGAGEMENT AND AWARENESS

Recognizing that sustainable water management extends beyond technical solutions, the institute has developed an extensive awareness program to engage students, faculty, and staff. Interactive initiatives such as painting competitions, photography contests, and slogan-making events help cultivate a culture of environmental consciousness. These programs not only educate stakeholders about water conservation but also inspire proactive participation in sustainable practices, transforming individual awareness into collective environmental responsibility.

FUTURE VISION AND SUSTAINABLE DEVELOPMENT

Looking forward, the institute’s water management strategy focuses on continuous improvement and progressive goal-setting. Key recommendations include maximizing treated water utilization, reducing groundwater extraction, implementing centralized real-time water monitoring, and developing comprehensive water usage policies. The long-term vision aims to create a replicable model of sustainable infrastructure that can be adopted by other educational institutions and organizations seeking to minimize their environmental footprint.

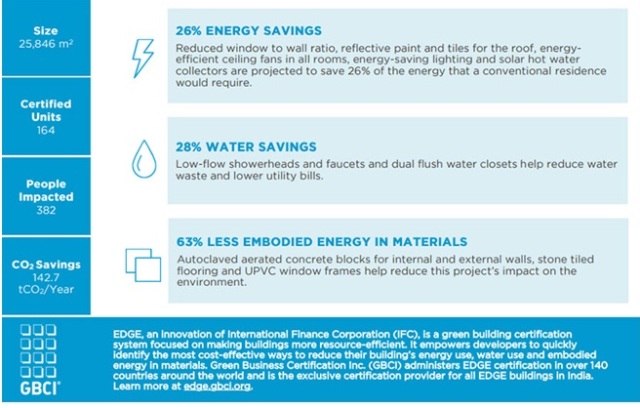

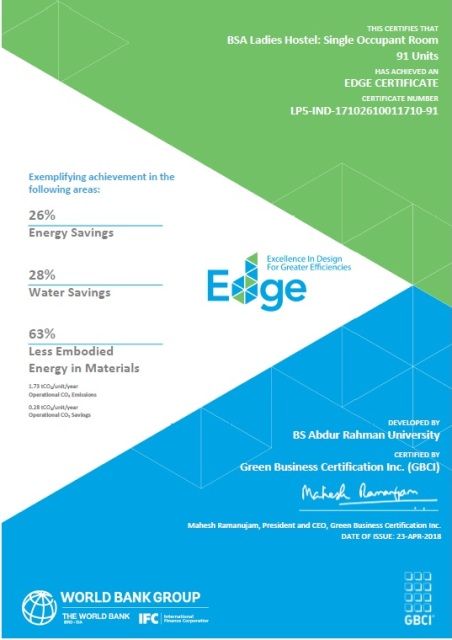

ACHIEVING EDGE CERTIFICATION

B.S. Abdur Rahman Crescent Institute of Science and Technology’s Ladies Hostel, which includes single and triple occupant rooms, has successfully achieved EDGE certification from the Green Business Certification Inc. (GBCI), highlighting the university’s commitment to sustainability and resource efficiency through significant energy, water, and material savings in its building design and operations. For the single-occupant rooms, there is a notable 26% reduction in energy consumption, largely due to energy-efficient features like reflective roofing and solar water heaters, alongside a 28% decrease in water usage thanks to low-flow fixtures, resulting in a remarkable 63% reduction in embodied energy from sustainable construction materials. The triple-occupant rooms reflect similar success, achieving a 27% savings in energy and water usage, with embodied energy in materials reduced by 61%. These accomplishments not only improve living conditions for residents but also align with the university’s broader sustainability goals. The EDGE certification reinforces the institution’s dedication to creating sustainable living environments and sets a benchmark for future construction projects, emphasizing the integration of sustainable practices in architecture and building management. Moving forward, the institute is committed to fostering a culture of sustainability, encouraging awareness and participation among all stakeholders in the pursuit of a greener future.

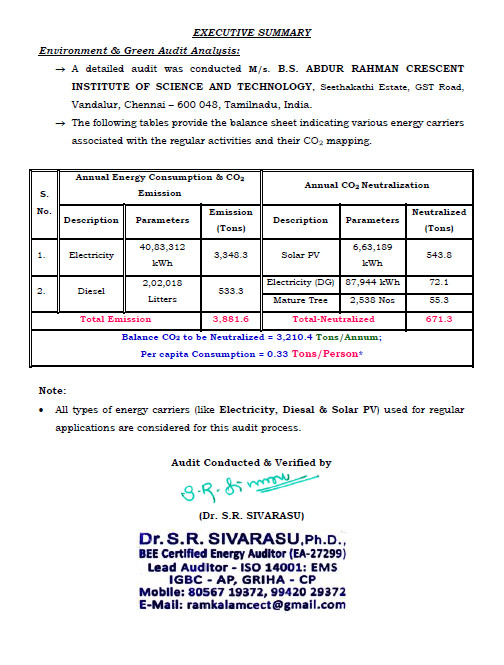

ENVIRONMENT, GREEN, AND WATER AUDIT PROCESS: A COMPREHENSIVE OVERVIEW

B.S. Abdur Rahman Crescent Institute of Science and Technology has developed a multifaceted approach to water management, focusing on diverse sources, efficient storage, and effective distribution systems. The institution utilizes a range of water sources, including reverse osmosis (RO) water for drinking purposes, bore water sourced from depths of up to 300 feet at prominent locations such as the Science Block, and multiple open wells strategically placed near hostels and the main canteen. Additionally, the college incorporates lorry water delivered and an extensive rainwater harvesting system (RWHS) deployed across various building blocks to capture runoff and enhance groundwater levels.

The college employs a detailed analysis of its water utilities to optimise water usage and storage, as outlined in a comprehensive report. For instance, the Main Building includes an underground sump with 80 kilolitres (KLD) capacity, supported by robust motor systems that enable efficient water delivery to multiple sub-units, including the MBA and Canteen blocks. In contrast, the Men’s Hostel features an impressive 1,100 KLD capacity, ensuring adequate supply for residents. Regular maintenance is integral to this system, with the management team ensuring that overhead tanks and storage facilities are cleaned every six months, thus guaranteeing the quality and safety of the water supplied throughout the campus.

The institution places considerable emphasis on sustainability, particularly through its rainwater harvesting initiatives. Rainwater is collected from building rooftops and routed via an effective piping system to dedicated pits that promote groundwater recharge. Plans are underway to expand the number of rainwater harvesting pits and conduct GIS studies to monitor improvements in the groundwater table over time. Such measures highlight the proactive role that B.S. Abdur Rahman Crescent Institute plays in enhancing water conservation and management practices while also addressing community needs through increased water availability.

GREEN BUILDINGS & CERTIFICATION

All existing buildings are registered with Indian Green Building Council (IGBC) for green building certification under IGBC – EB rating

- New buildings are constructed over the last six years and those under construction are registered with GBCI EDGE and USGBC LEED for green building certification for Gold rating.

- GBCI-EDGE Green building certification received for New Ladies Hostel & New staff quarters on 23.04.2018.

- Crescent School of Architecture block is conceived as a Net Zero Energy building and registered under USGBC-LEED for Gold rating certification.

GREEN BUILDING IN CONSTRUCTION

Sustainable and eco-friendly campus development has been adopted with following materials

- Grass Crete: Method of laying Grass paver flooring, walkways, sidewalks and driveways to improve storm water absorption and drainage

- Ash Crete: Fly ash (recycled) content with cement is being used for all Reinforced Cement concrete works.

- Low – VOC paints: Painting with low VOC less than 50gm/liter is using for all painting works – Nippon and Berger

- Engineered wood: MDF (Medium Densified Fibre) wood used for interior partition, doors and furniture’s.

- Structural Insulated Panels (SIP): Foam board wall panels are used for prefab structures such as class room and indoor game space.

- Insulated Concrete Forms: GFRC Technology being adopted to construct parent waiting guest rooms and essential staff quarters.

- Steel: Steel roof panels (recyclable) used for workshop roofing.

- Composites: Roof panels made of composite materials such as foam sandwiched between two metal sheets used for prefab class room ceiling.

- Fibreglass: Fibreglass is also used in insulation in the form of Fibreglass batts for interior partition works.

- AAC Blocks: Autoclaved Aerated Concrete blocks (non- toxic product) are used for the construction of all buildings to reduce low environmental impact.

- Thermatek Roof tile: Heat Resistant Terrace tiles are used for all buildings.

- VAV system: Variable air volume HVAC system is adopted to reduce energy consumption.

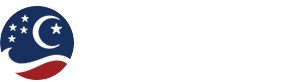

EDGE GREEN BUILDINGS AUDIT

Figure VI (3.4) – 1: Photographs showing the BSA Staff Quarters

The B.S. Abdur Rahman Crescent Institute of Science and Technology, located in Chennai, has prepared students in India to pursue careers in engineering, science and technology for over 40 years. In addition to inspiring innovation among its students, the university has also chosen to improve its campus by adding green buildings. The new women’s residences and staff quarters have many green features that have all been implemented at no additional cost to the university. When utility bills are taken into consideration, the result is a positive sum gain.

The university has many green features such as solar hot water collectors and energy-saving lighting systems to reduce energy consumption, and UPVC windows to reduce embodied energy in materials. Located in a region that experiences frequent droughts and shortages of water, the university can also conserve its supply of water with the help of low-flow showerheads and faucets and dual flush water closets. The university hopes to use EDGE for future buildings on the campus, to further its resource-efficient and environmentally-friendly approach.

SUMMARY OF EDGE CERTIFICATION REPORTS

The following reports summarize the achievements of various buildings at BS Abdur Rahman University in terms of energy efficiency, water conservation, and reduced embodied energy in materials. Each building has been certified under the EDGE (Excellence in Design for Greater Efficiencies) program, which is an initiative by the International Finance Corporation (IFC).

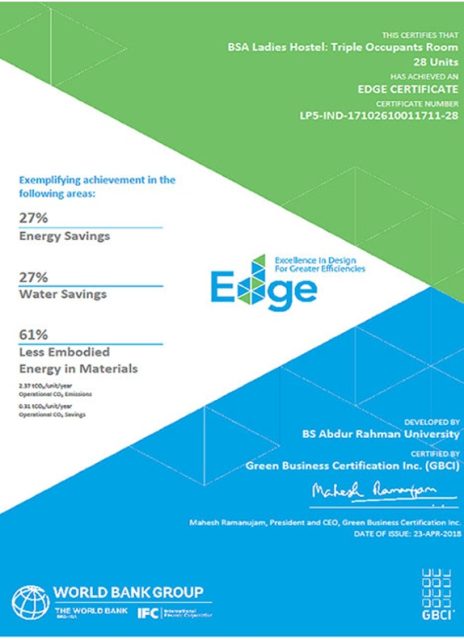

BSA Ladies Hostel: Triple Occupants Room (28 Units)

Energy Savings: 27%

Water Savings: 27%

Less Embodied Energy in Materials: 61%

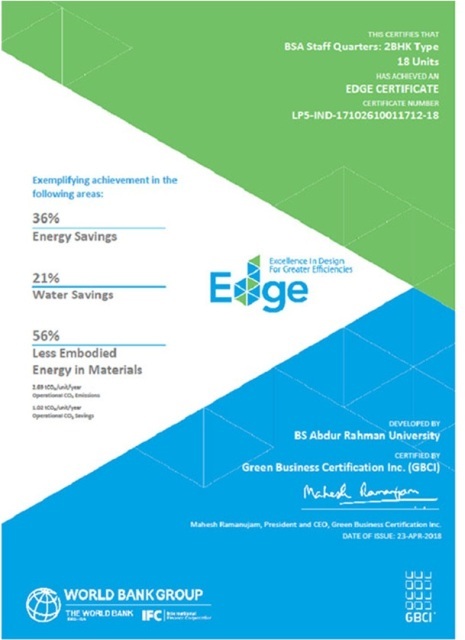

BSA Staff Quarters: 28HK Type (18 Units)

Energy Savings: 36%

Water Savings: 21%

Less Embodied Energy in Materials: 56%

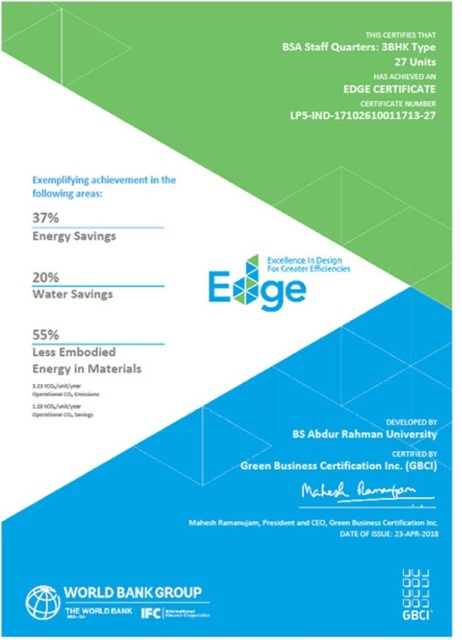

BSA Staff Quarters: 38HK Type (27 Units)

Energy Savings: 37%

Water Savings: 20%

Less Embodied Energy in Materials: 55%

BSA Ladies Hostel: Single Occupant Room (91 Units)

Energy Savings: 26%

Water Savings: 28%

Less Embodied Energy in Materials: 63%

BSA Staff Quarters: 28HK Type (18 Units)

Energy Savings: 36%

Water Savings: 21%

Less Embodied Energy in Materials: 56%

Overall Impact

The certifications demonstrate a commitment to sustainability and resource efficiency across the university’s facilities. The significant energy and water savings, along with reduced embodied energy, contribute to lower operational costs and a smaller environmental footprint. These achievements reflect the university’s dedication to creating a sustainable living and learning environment for its students and staff.

The B.S. Abdur Rahman Crescent Institute has received final EDGE certification from GBCI India.

Figure VI (3.4) – 2: Screenshot showing the gist of Statistics of Audit conducted by EDGE

EDGE GREEN BUILDING CERTIFICATION

Figure VI (3.4) – 3: GBCI-EDGE GREEN BUILDING Certification for Ladies Hostel

Figure VI (3.4) – 4: GBCI-EDGE GREEN BUILDING Certification for Ladies Hostel

Figure VI (3.4) – 5: GBCI- EDGE Certificate for Staff Quarters

Figure VI (3.4) – 6: GBCI- EDGE Certificate for Staff Quarters

Table VI (3.4) – 1: Indian Standards Adopted / Implemented for water conscious building

| S. No. | Name of the Building | Indian Standards |

| 1 | Extension of Mechanical Block | Loading Standards as per BIS-875, Seismic Force as per BIS-1893 and BIS – 456 https://www.bis.gov.in/ https://standardsbis.bsbedge.com/ https://www.bis.gov.in/standards/technical-department/national-building-code/ |

| 2 | Aeronautical Block | |

| 3 | Staff Quarters | |

| 4 | Ladies Hostel |

Design Brief on Electrification, Public Health Engineering Fire Fighting – Ladies Hostel

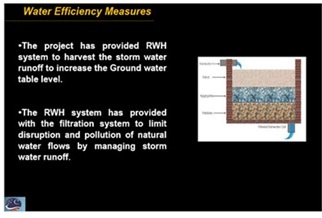

Figure VI (3.4) – 7: Water Efficiency Measures

1. SOURCE OF WATER, STORAGE AND DISTRIBUTION

Table- VI (3.4) – 2 shows the source of water, location of storage along with their application.

Table VI (3.4) – 2: Source of Water, Location of Storage and Application

Type of Water | Source | Application |

Fresh Water | RO Water | Drinking application |

Bore Water | 1. Science Block – 300 Ft | Utensil Cleaning, Bathing, Cloth Washing & Gardening |

Open Well | 1. Ladies Hostel – 30 Ft 2. Mens Hostel – 40 Ft 3. Near Main Canteen – 30 Ft | |

Lorry Water | 1.150 Tankers/Month (10,000/Tank) | |

Rain Water Harvesting System (RWHS) | 1. College/Life Science Block – 1 No 2. New Architecture Block –1 No 3. Computer Science Block – 1 No 4. Pharmacy Block – 1 No 5. MS Block – 5 No’s 6. Ladies Hostel – 3 No’s 7. New Staff Quarters – 6 No’s 8. Mens Hostel – 18 No’s 9. Library Block – 1 No | · Used to increase the ground water · To store building run-off only |

2. DETAILS OF THE WATER UTILITIES, STORAGE, MOTOR CAPACITY AND APPROXIMATE RUN HOURS

The following table VI (3.4) – 3 provides the details of the Water Utilities, Storage, Motor Capacity and Approximate Run Hours available inside the college for regular application.

Table VI (3.4) – 3: Details of the Water Utilities, Storage, Motor Capacity and Approximate Run Hours

S. No. | Location | Tank Capacity | Motor Capacity | Usage |

| 1. | Main Building (UG Sump) (Lorry + Open well) | 80 KLD |

3 * 7.5 H.P/5 kW | Main Block 3,000 – Litters * 5 No’s (Syntax) |

MBA Block 3,000 – Litters * 2 No’s (Syntax) | ||||

1st Year Block 3,000 – Litters * 4 No’s (Syntax) | ||||

Main Canteen 3,000 – Litters * 2 No’s (Syntax) | ||||

| 2. | Science Block | 60 KLD | Science Block | |

| (UG Sump) (Lorry + Open well + Bore well) | 2 * 7.5 H.P/5 kW | 3,000 – Litters * 4 No’s (Syntax) | ||

Pharmacy Block 3,000 – Litters * 2 No’s (Syntax) | ||||

GM Office 3,000 – Litters * 2 No’s (Syntax) | ||||

Power Room 3,000 – Litters * 2 No’s (Syntax) | ||||

3. | Mens Hostel – 1 (Lorry + Open well) | 1,100 KLD (New Sump Room) | 5 * 10 H.P/7.5 kW + 2 * 7.5 H.P/5 kW | A – Block 3,000 – Litters * 7 No’s (Syntax) |

B – Block 3,000 – Litters * 6 No’s (Syntax) | ||||

C – Block 3,000 – Litters * 9 No’s (Syntax) | ||||

D – Block 3,000 – Litters * 11 No’s (Syntax) | ||||

| 4. | Mens Hostel – 1 (Lorry + Open well) | 40 KLD (Main Block + Mess) | 1 * 7.5 H.P/5 kW + 3 * 5 H.P/3.7 kW | Main Block 3,000 – Litters * 10 No’s (Syntax) |

Mess 3,000 – Litters * 5 No’s | ||||

| 5. | Mens Hostel – 2 (Open well) | 60 KLD (PG Block) | 2 * 7.5 H.P/5 kW + 1 * 5 H.P/3.7 kW | Mosque 3,000 – Litters * 2 No’s |

PG Block 3,000 – Litters * 6 No’s | ||||

Incubation Block 3,000 – Litters * 4 No’s | ||||

| 6. | Ladies Hostel (Lorry Water) | 180 KLD | 3 * 5 H.P/3.7 kW | Main Block 3,000 – Litters * 7 No’s |

| 7. | Annuxer Block (Open well) | 30 Ft | 1 * 5 H.P/3.7 kW | RCC Tank 15,000 Litters |

| R.O Water | ||||

| 1. | Main Building RO Plant | Water From Main Block Syntax Tank | Main Block – 3,000 Litter * 1 No MBA Block – 3,000 Litter * 1 No | |

2. | Science Block RO Plant | Water From Science Block Syntax Tank | Science Block+Pharmacy Block+Canteen – 3,000 Litters * 1 No | |

3. | New Architech RO Plant | Water From New Architech Block UG Sump | New Architech – 3,000 Litters * 1 No | |

4. | Auditorium RO Plant | Water From New Architech Block UG Sump | Auditorium – 3,000 Litters * 1 No | |

5. | Old Staff Quaters RO Plant | Water From New Architech Block UG Sump | Old Staff Quarters – 3,000 Litters * 1 No | |

6. | Chanceller Villa RO Plant | Water From New Architech Block UG Sump | Chanceller Villa – 3,000 Litters * 1 No | |

7. | N.Staff Quaters RO Plant | Water From New Architech Block UG Sump | N.Staff Quaters – 3,000 Litters * 1 No | |

8. | MS Block RO Plant | Water From New Architech Block UG Sump |

MS Block – 3,000 Litters * 1 No | |

| 9. | LS Block RO Plant | Water From LS Block UG Sump | LS Block – 3,000 Litters * 1 No | |

| 10. | Mens Hostel RO Plant | Water From New Sump Room | A,B,C,D Block – 3,000 Litters *4 No’s | |

| 11. | Mess + Main Block RO Plant | Water From Mess Block Syntax Tank | Mess + Main Block – 3,000 *2 No’s | |

| 12. | Ladies Hostel RO Plant | Water From New Block Cement Tank | New Block – 5,000 – RCC Tank | |

Note:

- Over Head (OH) tanks are made using Syntax.

- The maintenance team ensure to clean the tank for six months once.

- Bleaching power is mostly used to clean the inside tank.

3. TREATED WATER FOR DRINKING APPLICATION

- The college management is keen on providing uninterrupted, safe and healthy drinking water to all; throughout the

- Water dispenser are provided at appropriate places offering the treated water for the students (Both Normal and Hot temperature)

- The overhead tanks storing the well water are cleaned at regular intervals and the water management team has been maintaining a cleaning schedule Utensil Cleaning, Bathing & Cloth Washing.

Figure VI (3.4) – 8: PVC and Metal Based Taping System for Water Distribution Line

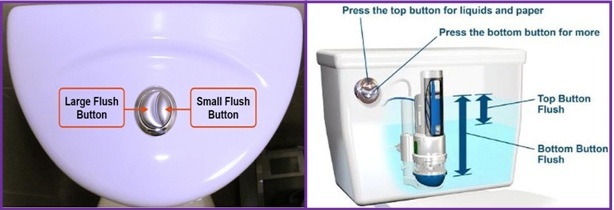

4. WATER SAVINGS IN FOREIGN TOILETS

- The list of availability of Indian & Foreign style toilets are presented in the below Table- VI (3.4) – 4.

Table VI (3.4) – 4: List of Indian & Foreign Style Toilets

| S. No. | Location | Description (Quantity) | |||

| Indian | Foreign | ||||

| 1. | Auditorium Block | 29 | 16 | ||

| 2. | Main Block | 24 | 6 | ||

| 3. | MBA Block (CBS) | 11 | 8 | ||

| 4. | Science Block (CSE) | 25 | 7 | ||

| 5. | Basic Science Block | 27 | 5 | ||

| 6. | Pharmacy Department | 19 | 6 | ||

| 7. | Mechanical Science Block | – | 89 | ||

| 8. | Life Science Block | – | 37 | ||

| 9. | New Architecture Block | – | 24 | ||

| 10. | Common Toilet Near Ground | – | 10 | ||

| 11. | Arabic College & Hostel | 44 | – | ||

| 12. | New Toilet Near MBA Block | – | 18 | ||

| 13. | Estate Office | 1 | 3 | ||

| 14. | Common Toilet in Sports Village | – | 4 | ||

| 15. | Common Toilet Towards Men’s Hostel | 2 | 6 | ||

| 16. | Bio Toilet Near Security Cabin & Near DATA Centre | – | 4 | ||

| 17. | CIIC Block | 5 | 40 | ||

| 18. | Firest Year Canteen | – | 4 | ||

| Total | 187 | 287 | |||

In general, the flush tank capacity may be 8 to 10 Litres (depends on make and model). Water savings also leads to power saving it saves the operating duration of the water pumps directly.

Figure VI (3.4) – 9: Flush Tank Button for efficient water use

5. RAIN WATER HARVESTING (RWH) – FROM BUILDING ROOF AREA & RUN-OFF AREA

- THE AUDIT TEAM appreciates the effects taken by the management of S. ABDUR RAHMAN CRESCENT INSTITUTE OF SCIENCE AND TECHNOLOGY for harvesting the rain water almost in all buildings.

- The roof area is so arranged to collect the rainwater and then passed through proper piping system, and then bring back to the RWH pits which are located close to each

- The building run off are collected through each pit mostly located in each building. Common area and road run-off are properly collected and routed to nearby water body.

Figure VI (3.4) – 10: Rain Water Harvesting Pit

6. GENERAL RECOMMENDATIONS FOR RAIN WATER HARVESTING

- RWH has been fitted with their specifications indicating their i) year of installation, ii) approximate average rainfall and duration in the RWH location and iii) filter cleaning schedule (if any).

- Conduct a GIS based study on the improvement of ground water table especially before the rainy session and after rainy Compare the data and ensure that the water table improves due to percolation of rain water.

- Similar study mast be conducted (in future) before installing an RWH and after RWH.

- Increase the of RWH pits and may be developed to place at least 2 per building.

Figure VI (3.4) – 11: Sample Name Board in front a Rain Water Harvesting System

7. GENERAL RECOMMENDATIONS

- It is advisable to replace all the old taps without aerator into aerator-based taps in a phased

- Aerators helps to reduce and regulate water flow and also offer the following benefits;

- Lower Water Bills & Improved Water Pressure

- Increased Filtration & Minimized Splashing

- ll the pump motor must be fitted and controlled by floating sensor and hence the motors are automatically ON and OFF. It avoids the overflow; saves water and electrical energy.

- All the buildings are fitted with water flow meters & hence the water utilization must be properly accounted. Similar to the water flow meter; energy consumption of all pumping motors is recorded using panel board meters.

- Fault and leakage in the water distribution line will be promptly informed by the respective in-charges to the maintenance team and immediately arrested.

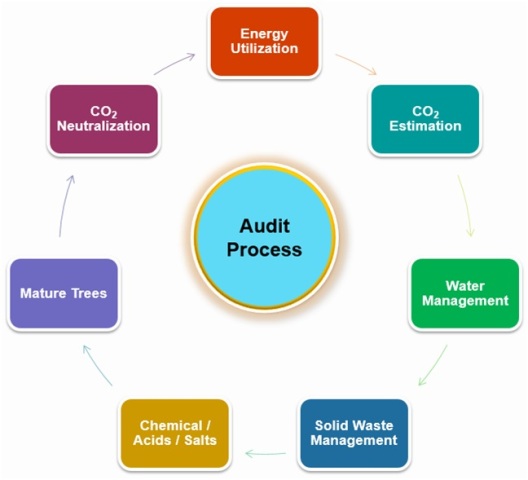

Table VI (3.4) – 5 : Environment & Green Audit Report Details

Chapter No. | Description | Page No. |

1 | Acknowledgement | 3 |

2 | Introduction to Environment-Green Audit Process | 6 |

3 | Executive Summary | 10 |

PART-A: ENVIRONMENTAL AUDIT REPORT | ||

4 | Study on Energy Consumption Pattern | 12 |

5 | Estimation of CO2 Emission and Neutralization | 15 |

6 | Usage of Chemicals, Salts & Acids | 18 |

PART-B: GREEN AUDIT REPORT | ||

7 | Water Utilization, Conservation & Water Management | 22 |

8 | Waste Handling & Management | 30 |

9 | Assessment on List of Mature Trees and Green Energy Generation | 38 |

10 | Audit Summary & Conclusion | 45 |

Annexure | Authorised Certificates of Auditor | 48 |

Figure VI (3.4) – 12: Environment and Green Audit Process

Water Management and Reuse Policy

Issue: 04; Revised on 2023

| Policy Created on | July 2009 |

| 1st Revision amended on | IQAC Meeting held on 27th October 2017 |

| 2nd Revision amended on | IQAC Meeting held on 31st March 2021 |

| 3rd Revision amended on | IQAC Meeting held on 16th June 2023 |

6.1 STATEMENT OF POLICY

The B.S. Abdur Rahman Crescent Institute of Science and Technology is committed to achieving the following objectives in alignment with Sustainable Development Goal 6 (SDG 6) – Clean Water and Sanitation:

- a) Ensure universal and equitable access to safe and affordable drinking water for all stakeholders.

- b) Provide adequate and equitable sanitation and hygiene for all, with special attention to the needs of women, girls, and vulnerable groups.

- c) Improve water quality by reducing pollution, eliminating dumping, and minimizing the release of hazardous chemicals and materials.

- d) Halve the proportion of untreated wastewater and substantially increase recycling and safe reuse globally.

- e) Substantially increase water-use efficiency across all sectors and ensure sustainable withdrawals and freshwater supply to address water scarcity.

- f) Implement integrated water resources management at all levels, including transboundary cooperation as appropriate.

- g) Protect and restore water-related ecosystems, including mountains, forests, wetlands, rivers, aquifers, and lakes.

- h) Expand international cooperation and capacity-building support to developing countries in water- and sanitation-related activities and programs.

- i) Support and strengthen the participation of local communities in improving water and sanitation management.

6.2 REASON FOR THIS POLICY

The policy aims to provide all stakeholders with adequate water supply, sanitation, and hygiene. It emphasises maximising the collection and treatment of sewage generated and the reuse of treated wastewater sustainably, thereby reducing dependency on freshwater resources. The policy promotes treating wastewater as an economic resource.

6.3 RESPONSIBILITIES

6.3.1 Policy Principles

- a) The campus shall provide adequate water supply and maximize water reuse by adhering to the following principles:

- Equitable access to safe and affordable drinking water for all stakeholders.

- Access to adequate sanitation and hygiene, ending open defecation, with special attention to vulnerable groups.

- Calculation of water usage per person (students, staff, and faculty) annually.

- Improving water quality by reducing pollution and increasing recycling and safe reuse.

- Utilization of recycled/treated wastewater for beneficial purposes, such as irrigation and toilet flushing.

- Implementation of integrated water resources management at all levels.

- Protection and restoration of water-related ecosystems on campus.

- Expansion of rainwater harvesting initiatives.

- Collaboration with government, NGOs, and industries in water-related activities.

- Support for student and staff participation in water management.

6.4.1 Water Reuse Policy Objectives

- Establish a comprehensive policy to maximize water reuse across the university.

- Ensure that all new buildings adhere to water-conscious building standards that facilitate water reuse.

- Implement systems for tracking and measuring water consumption and reuse.

6.4.2 Water Reuse

- Water Reuse Policy: maximise water reuse across the university.

- Water Reuse Measurement: Measure water reuse across the university.

6.5 DISSEMINATION OF POLICY

- a) Display signage promoting water use efficiency across the campus.

- b) Conduct awareness programs at regular intervals to increase water-use efficiency.

- c) Post the policy on the Institute’s website and update it as necessary.

6.6 ENFORCEMENT OF POLICY

- a) The Director (Planning & Development) and Deputy Director monitor compliance and address breaches.

- b) Awareness of the policy among students, staff, and visitors is essential.

- c) Breaches may lead to disciplinary action as per the Institute’s code of conduct.

REGISTRAR