Crescent Sustainability Initiatives

Partnerships for the Goals (SDG 17)

B.S. Abdur Rahman Crescent Institute of Science and Technology (BSACIST) has taken significant strides in promoting sustainable waste management practices, on Responsible Consumption and Production. The institute has implemented comprehensive strategies for managing solid waste, liquid waste, and electronic waste (e-waste), showcasing its dedication to environmental sustainability. Through a structured approach, BSACIST segregates waste into organic, recyclable, and inert categories, ensuring effective processing and disposal. Notably, the institute has diverted over 1,44,655 kg of waste from landfills to recycling initiatives, contributing to substantial environmental benefits.

In solid waste management, BSACIST employs a two-bin system for waste collection and has established a dedicated team for processing the segregated waste. The institute has also invested in infrastructure, including a biogas plant and incinerators, to manage food waste and sanitary products responsibly. With a focus on liquid waste, BSACIST operates two sewage treatment plants that recycle treated water for landscaping and toilet flushing, thereby reducing reliance on freshwater resources. Furthermore, the institute actively manages e-waste by ensuring proper disposal through authorized vendors, thus preventing hazardous materials from contaminating the environment.

Overall, BSACIST’s initiatives reflect a holistic approach to waste management, fostering a culture of sustainability within the campus community. By engaging stakeholders through awareness programs and training sessions, the institute empowers individuals to adopt responsible consumption practices, ultimately contributing to a greener and more sustainable future.

- S. Abdur Rahman Crescent Institute of Science and Technology takes initiatives to manage the different types of waste generated in the campus. The waste management includes

- Solid waste management

- Liquid waste management

- E-waste management

- S. Abdur Rahman Crescent Institute of Science and Technology is committed to ensure that the built infrastructure of the institute has sustainability as a core principle in maintenance management of the campus.

- An exclusive Estate Office of BSACIST aspires to follow a range of sustainable design features and practices implemented to build and maintain the institute as a complete green and sustainable campus continuously.

- The solid waste management is practiced to safely dispose the waste generated at the campus by way of segregating the waste as organic waste, recyclable waste and inert waste and processing the waste thus segregated.

- Implementation of solid waste management inside the campus is maintained by our inhouse team of Rs. 9.0 lakhs per annum is spend towards salary for the staffs.

- Every year our institute contributes waste papers towards national recycling initiative organized by ITC Ltd (paper boards & specialty paper division) which is equivalent to saving 750 trees on an average.

- Our Institute received certificate of Appreciation from Green Services Trust for partnering in implementing solid waste management project in the campus in an environment friendly manner and diverted 1,44,655 Kg of waste from landfill to recycling during the year 2017-2018.

WASTE QUANTIFICATION DATA – FROM 2016 TO DECEMBER 2023:

- Total Waste Collected : 39,60,472 Kgs.

- Total Organic waste : 15,70,857 Kgs.

- Total Recyclable waste : 2,79,459 Kgs.

- Total Inert waste : 21,10,156 Kgs.

ACTIVITIES CARRIED OUT

- Two bins system is followed for waste collection one for organic and one for recyclables.

- Collection of waste from the campus is done through a tractor and with the support of six-man power.

- The collected segregated waste will be unloaded at the waste processing yard and processed through 15 staff called as ‘Green friends’.

- The waste generated at the campus will be processing as per SWM Rules 2016

- Bio-degradable waste is composted under windrow composing method.

- Recyclable waste is further segregated and disposed through vendors on need basis.

- Sanitary napkins waste is safely disposed using an incinerator fitted with wet scrubber for pollution control

- Food waste is fed in the bio gas plant and the gas is utilized for cooking purpose in the canteen

- E-waste and hazardous waste is handed over to the authorized processors and certificate of destruction as per norms is obtained from the processor.

- 2 Supervisory staff also been engaged for coordination and awareness creation activity at the campus and 10 green friends are engaged for waste collection and maintenance of bio gas plant.

- Different types of Solid waste management Training and Awareness program conducted to college students, staff, Housekeeping workers, security and green friends.

- The harvested bio compost will be given to the estate office every month, nearly 2000kgs, for garden use

- Every month around 4000kg of recyclable waste is removed from waste yard for process.

- The University takes sufficient measures to treat the wastewater generated within the premises and it ensures that the treated water is reused within the campus. Estate office has established suitable and sustainable sewage treatment plants with the design features to completely treat the wastewater generated in the university.

- 2 nos. of Sewage treatment plants of 250KLD capacity are available, one for Men’s Hostel and one for Institute campus.

- The sewage generated in the University is generally characterized by the presence of organic, inorganic and suspended solids.

- The chain of treatment is aimed to remove such pollutants from the wastewater so that it can be effectively reused.

- The treatment system consists of preliminary treatment system followed by the primary and secondary treatment process.

- The preliminary treatment system aims the removal of floating bodies and grits from the waste water. Bar Screens are used in the treatment plant to remove materials like plastics and other floating objects.

- The grit chambers are used to remove sand and silts from the wastewater.

- The primary sedimentation tank helps in the removal of the suspended solids.

- The biological treatment system is the secondary treatment process used in the removal of organics from the wastewater

- The suspended solids are removed using the primary sedimentation tank and after this the wastewater is subjected to biological treatment to remove the organic content from the waste.

- The secondary treatment process is incorporated with ECO-BIO BLOCK so as to increase the efficiency of the treatment system.

- The Eco-Bio Bricks helps in the attachment of bacteria in the treatment system and helps in the better removal of organic content from the wastewater.

- This attached system will also help the treatment system to handle shock loadings if there is an increase in the organic loading rate in the biological treatment system.

- The sewage treatment plant is working on the principle of attached growth aerobic system (Eco-Bio Block) followed by sand filter and carbon filter.

- The carbon and sand filter ensures that any amount of organics that is left in the wastewater is suitably adsorbed from the wastewater and it is stored in the collection tank.

- The entire Sewage Treatment Plant is periodically subjected to maintenance regularly.

- The working of all the pumps and valves are checked periodically to ensure the smooth functioning of the sewage treatment plant.

- The treated water is used for landscaping and toilet flushing purpose.

- This helps the university to reduce its dependency of fresh water from wells for gardening.

- The physical, chemical and biological characteristics of the treated water are tested to ensure the efficiency of the treatment systems.

- Some of the important parameters checked include pH, solids, Chemical oxygen demand, Biochemical oxygen demand, Nitrates, chlorides etc.

- The treated wastewater is checked periodically to ensure its quality so that it can be effectively reused for gardening and as well for the toilet flushing.

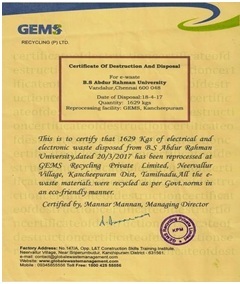

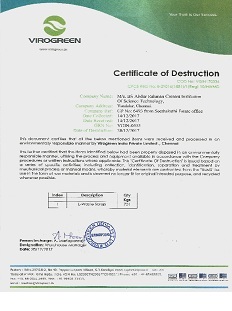

- The institute takes sufficient measures to dispose the e-waste generated inside the campus properly.

- Our Institute also takes initiatives to reduce the generation of e-waste in the campus

- All obsolete electrical and electronic waste is disposed as e-waste to vendors for proper destruction without damaging the environment and certificate for such destruction and disposal are obtained.

- Electronic waste that are disposed includes

- Old TVs, computer monitors, printers, scanners, keyboards, mouse, Radio, Phones, Fax, Photocopy machines, cables from computer laboratories of various departments

- Flip flops, memory chips, motherboard, compact discs, cartridges

- Kitchen equipment from staff quarters and hostels like toasters, coffee makers, microwave ovens etc.

- Laboratory equipment’s from various departments.

- Totally 2330kg E –waste generated is destructed every year.

- The condemned electronic equipment’s are handed over to the estate office on a regular basis by the departments after checking or inspection by a committee consisting of Senior Professors. Once the equipment’s are certified as obsolete or non-working it is condemned and handed to estate office.

- This E waste which is collected is then disposed to vendors.

- It is also ensured that the generated E wastes are not disposed along with the other solid waste generated in the campus.

- Collection of e waste separately is a sustainable approach to prevent such waste reaching the landfills and also provides an opportunity to recycle such waste.

- The e waste collected separately is handed over to the vendors for recycling or disposal.

- The company GEMS recycling PVT Limited, Neervallur Village, Kanchipuram district, Tamilnadu collects all the waste.

- Our institute has received certificate for destruction and disposal of waste from the company for reprocessing/recycling the waste without harming the environment in an ecofriendly manner.

- A Standard Operating Procedure has been evolved for handling the waste disposal system.

- Awareness is also created among faculty, students and also office bearers on the usage of electronic goods, its usage and also on the ways that it has to be collected and disposed

- Electronic goods are put to optimum use; the minor repairs are set right by the supporting staff and the Laboratory non-teaching faculty and the major repairs, by the professional technicians, and are reused.

- The damaged computers are used by the instructors in the practical sessions. Finally, they are exchanged with the local dealers.

- UPS Batteries are recharged / repaired / exchanged by the suppliers.

- The waste compact discs are reused by civil engineering/architecture students for decoration/participation in competitions.

- Steel, Iron, Aluminum, and Wood from construction site will be sent to scrap shop and further to recycling plants.

- Steel, Iron, Aluminum, from laboratories will be sent to scrap shop and further to recycling plants.

- All the communication of the institute is through Internet within the teaching and nonteaching faculty members.

- There are hardly any floppies or CDs used for day to day operations.

DOCUMENTAL EVIDENCES FOR SOLID WASTE MANAGEMENT

The solid waste management project is intended to safely dispose the waste generated at the campus by way of segregating the waste as organic waste, recyclable waste and inert waste and processing the waste thus segregated.

Figure XVII (3.12) – 1 : Certificate of Appreciation for Implementing Solid Waste Management Project

Figure XVII (3.12) – 2 : Certificate of Appreciation for Recycling Paper Waste

Figure XVII (3.12) – 3 : Segregation of Solid Waste

Figure XVII (3.12) – 4 : Windrow Formation and Rotation

Table XVII (3.12) – 1 : WASTE COLLECTION DATA FROM 2016 TO 2023

S.No | Year | Organic waste in Kg | Recycle waste Kg | Inert waste Kg | Total Waste in Kg |

1 | 2016 | 73,924 | 34,950 | 1,03,870 | 2,12,744 |

2 | 2017 | 82,245 | 54,845 | 13,509 | 1,50,599 |

3 | 2018 | 1,24,615 | 78,098 | 19,578 | 2,22,291 |

4 | 2019 | 1,11,103 | 40,737 | 77,546 | 2,29,386 |

5 | 2020 | 65,270 | 9,016 | 3,77,583 | 4,51,869 |

6 | 2021 | 24,570 | 8,571 | 6,17,600 | 6,50,741 |

7 | 2022 | 9,61,330 | 25,912 | 87,750 | 10,74,992 |

8 | 2023 | 1,27,800 | 27,330 | 8,12,720 | 9,67,850 |

TOTAL | 15,70,857 | 2,79,459 | 21,10,156 | 39,60,472 | |

BSA CRESCENT INSTITUTE OF SCIENCE & TECHNOLOGY – REPORT

Our endeavour at the college involved multifaceted initiatives aimed at fostering awareness, responsibility, and sustainability within the campus community. Through a series of meticulously orchestrated awareness sessions, we engaged various stakeholders including students, faculty, residential community members, hostellers, cooking teams and the housekeeping team. These sessions not only disseminated crucial information but also cultivated a culture of conscientiousness and accountability.

Moreover, we bolstered our commitment by deploying a dedicated supervisor, ensuring continuous monitoring and support for the implemented strategies. This proactive measure served to reinforce the importance of our efforts and provided a tangible presence to address any emerging challenges promptly. Central to our mission was the cloth waste collection drive, which served as a poignant reminder of the significance of environmental stewardship. By collecting discarded clothing items, we not only diverted waste from landfills but also contributed to social welfare through donations of wearable garments and environmentally responsible recycling practices.

In summary, our comprehensive approach underscores the vital role of our service in fostering a sustainable and inclusive environment within the college community. By empowering individuals with knowledge, resources, and opportunities for positive action, we strive to inspire lasting change and leave a meaningful impact on both the campus and beyond. We have conducted trainings to different stakeholders at different intervals in the month of November & December 2023.

Figure XVII (3.12) – 5 : Empowering Individuals with Knowledge, Resources, And Opportunities For Positive Action

Three bin system being implemented at the residential community as a part of our waste Management intervention

SOLID WASTE MANAGEMENT – ECOBIN (250 KGS / DAY)

Figure XVII (3.12) – 6 : 250Kg Ecobin in BSACIST for the management of food waste

Operating Procedures

Food waste after segregate loaded and mixed with 10-15% of saw dust +0.1% Bioculum. Now the mixture lifted into feeding port of Ecobin. In the tank, mixing operation will be done with regular time intervals in a day by day using main agitator derive.

Air will pass through into the tank by using blower with regular time intervals. Repeating mixture operation for feeding 250kgs per day. After repeating the activities for 15 days’ compost developed at the bottom.

Around 26,240kgs of manure collected till December 2023 and used for fertilizing the soil by toping up in the soil.

Figure XVII (3.12) – 7 : ECO-BIN

SOLID WASTE MANAGEMENT – GARBAGE INCINERATOR

- Garbage Incinerator machine installed in our campus/solid waste management yard with 50kg/hr. capacity reducing waste product to inert ash.

- Daily generation 500kg/day and generated fly ash being used as manure.

- Incinerated item will be less than 10% of their original bulk when reduced to ash

- Use for incinerator of waste paper, tea cup, Dry garbage and kitchen dry waste.

- Transport cost from point of work generation to disposal site are dramatically reduced.

- Around 1,16,280kgs of waste collected and compost 19,775kg ash generated till December 2023 as an alternate solution to landfill.

Figure XVII (3.12) – 8 : GARBAGE INCINERATOR

SOLID WASTE MANAGEMENT – SANITARY INCINERATOR

Figure XVII (3.12) – 9 : SANITARY INCINERATOR

- Incinerator machine has been installed to dispose sanitary napkins.

- Separate bins are provided in all ladies’ toilets in university and in Ladies Hostel to separate the napkins from other waste.

- Wet scrubber is attached at the outlet of burner where the fumes gets scrubbed in water and gets filtered to remove the harmful emissions. Separate Napkin destroyer machine has installed in Ladies hostel 5 Nos and 1 in Medical Hall.

SOLID WASTE MANAGEMENT – BIO-GAS PLANT

A Biogas plant of 50 m3 capacity for Ladies Hostel was commissioned in June 2017. The gas generated from the plant is utilized for cooking in Ladies Hostel Mess Kitchen.

Figure XVII (3.12) – 10 : Biogas Plant

Figure XVII (3.12) – 10 : Food waste feed in to Bio Gas Plant

BIO GAS GENERATION FOR THE PERIOD OF JUNE 2017 – DEC 2023 | |||

| |||

Year | Total Gas consumed (cum) | Equivalent to LPG (KG) | Cost Saved |

2017 | 917 | 412.35 | 29121 |

2018 | 1137.6 | 511.89 | 36485 |

2019 | 2615 | 1176.1 | 78010 |

2020 | 378 | 170.1 | 8097 |

2021 | 192 | 86.4 | 4706 |

2022 | 1400 | 639 | 34595 |

2023 | 211 | 94.95 | 11226 |

Total | 6850.6 | 3090.8 | 202240 |

BIOBOX

Our Institute has established BIO BOX unit of 50Kg/day capacity in association with M/S.Kankyo Group of Companies to generate biogas from various organic solid waste.

BIOBOX- Biogas generation unit

Pyrolysis unit

PYRO-CRACKER

Our Institute has established Pyro- Cracker unit of 25 Kg/ Batch capacity in association with M/S.Kanyo Group of Companies for thermal pyrolytic degradation of plastic, biomass and mixed garbage.

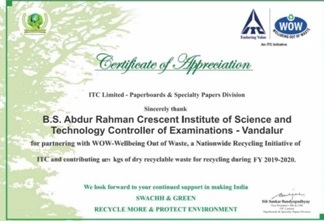

CSIR – CLRI SPONSORED PROJECT – BIOGAS PLANT 500 KGS/DAY (ON GOING)

Establishment of new Biogas plant 500kg/day at Men’s Hostel

Erection & Commissioning stageProcess flow Diagram

| NEW 500KG BIO GAS GENERATION FOR THE PERIOD OF SEP 2021 to DECEMBER 2023 IN MEN’S HOSTEL | |||

| Month | Total Gas consumed (cum) | Equivalent to LPG (KG) | Cost Saved |

| Sep-21 | 27 | 3.5 | 3,150 |

| Oct-21 | 150 | 10.725 | 9,652 |

| Nov-21 | 188.95 | 13.496 | 12,146 |

| Dec-21 | 320.3 | 22.87 | 20,590 |

| Jan-22 | 155 | 56 | 3,616 |

| Feb-22 | 45 | 24 | 2,916 |

| Mar-22 | 103 | 48 | 7,420 |

| Apr-22 | 188 | 92 | 13,470 |

| May-22 | 249 | 131 | 18,132 |

| Jun-22 | 319 | 164 | 22,815 |

| Jul-22 | 292 | 146 | 20,925 |

| Aug-22 | 194 | 98 | 13,905 |

| Sep-22 | 383 | 188 | 27,405 |

| Oct-22 | 279 | 148 | 19,980 |

| Nov-22 | 423 | 224 | 30,260 |

| Dec-22 | 90 | 45 | 6,440 |

| Jan-23 | 17 | 7.65 | 771 |

| Feb to Aug 23 | Not working | ||

| Sep-23 | 11 | 4.95 | 441 |

| Oct-23 | 23 | 10.35 | 1,033 |

| Nov-23 | 15 | 6.75 | 689 |

| Dec-23 | 11 | 4.95 | 502 |

| Total | 3483.25 | 1,449.24 | 236258 |

- Biogas Plant 500 kgs/day from CSIR-CLRI, Govt. of India, Chennai funded by DST New Delhi in collaboration with KANKYO Technologies.

- To handle the food waste generated from hostel kitchens and canteens

- It will generate 15-20 m3/day gas from the plant and the same will be utilized for our cooking needs at Hostel kitchens and Canteens.

- The total cost of project is 35 lakhs. (Crescent Contributed 10 lakh).

LIQUID WASTE MANAGEMENT – SEWAGE TREATMENT PLANT – 500KLD

- 2 nos. of Sewage treatment plants of 250KLD capacity are available, one for Men’s Hostel and one for Institute campus. The STP is of Eco-Bio Block type. The treated water is used for landscaping and toilet flushing purpose.

- The sewage treatment plant is working on the principle of attached growth aerobic system (Eco-Bio bricks) followed by sand filter and carbon filter. The treated water is having a COD about 100 mg/L and BOD about 16 mg/L.

DETAILS OF SEWAGE TREATMENT PLANTS

| Location | Capacity | Remarks |

| College campus | 250KLD | Commissioned in 2003 as a 150KLd plant. Revamped and capacity increased to 250KLD in 2015 |

| Men’s Hostel | 350KLD | 250KLDCommissioned in 2014.100KLD additional added in2023 |

DETAILS OF WASTEWATER GENERATION

Sewage Treatment Plant Recycled Water Detail for the period November 2017 to December 2023 | ||||

Sl.No. | Year | No.of Loads | Total Qty. | Qty. of treated |

1 | 2017 | 17640 | 17,64,00,000 | 14,52,70,800 |

2 | 2018 | 14890 | 14,89,00,000 | 12,68,54,000 |

3 | 2019 | 15381 | 15,38,10,000 | 13,05,06,000 |

4 | 2020 | 7265 | 72,66,50,000 | 8,82,46,200 |

5 | 2021 | 8390 | 8,39,00,000 | 9,37,65,000 |

6 | 2022 | 17192 | 17,19,20,000 | 58,15,000 |

7 | 2023 | 16660 | 16,66,00,000 | 15,92,58,000 |

|

| 97418 | 97,41,80,000 | 74,97,15,000 |

MIRA CARBON SEWAGE TREATMENT PLANT

Our Institute has established MIRACARBON SEWAGE TREATMENT PLANTof 2 m3 capacity in association with M/S.Kanyo Group of Companies to treat domestic wastewater generated from the Institute.

E-WASTE MANAGEMENT

All obsolete electrical and electronic waste is disposed as e-waste to vendors for proper destruction without damaging the environment and certificate for such destruction and disposal are obtained. Totally 2330kg E –waste destructed in the year 2017.

CERTIFICATE FOR DESTRUCTION OF E WASTE

CERTIFICATE FOR DESTRUCTION OF E WASTE

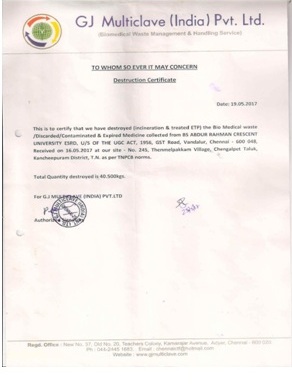

BIO-WASTE MANAGEMENT

All biological waste generated from Life Science Department and Medical Centre is disposed as bio-waste to vendors for proper destruction without damaging the environment and certificate for such destruction and disposal are obtained.

CERTIFICATE FOR DESTRUCTION OF BIO MEDICAL WASTE

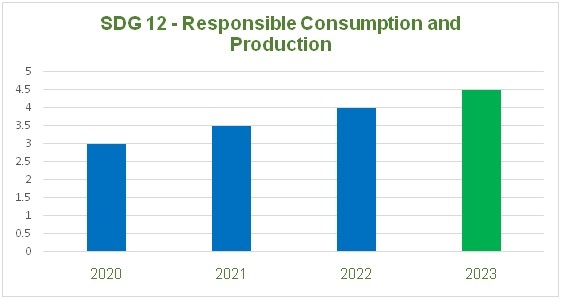

SDG 12: Responsible Consumption and Production

| 4 to 5 | There is significant progress in effective implementation compared to the previous year |

| 3 to 4 | The necessary processes/activities (Responsible consumption and production, Waste recycling, Publication of a sustainability report) have been implemented |

| 2 to 3 | There is an explicit plan to address the ‘Responsible Consumption and Production’ and necessitated processes have been initiated |

| 1 to 2 | There is an understanding and willingness to contribute effectively for achieving the UN targets of SDG 12 |

| 0 to 1 | There is no/partial willingness and plan to contribute for achieving the UN targets of SDG 12 Responsible Consumption and Production |

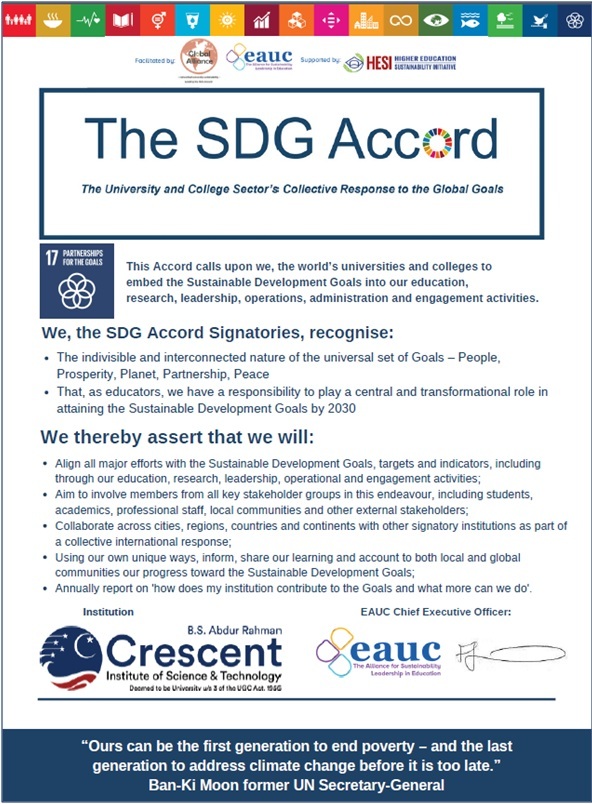

Please find the Report: SDG ACCORD REPORT