B.S. Abdur Rahman Crescent Institute of Science and Technology (BSACIST) is committed to ensuring safe, affordable, and reliable access to clean water while safeguarding water quality and ecosystems. We advance wastewater treatment and pollution prevention, and promote water-conscious practices. We strengthen water reuse and measurement, and track consumption to drive efficiency. Our ongoing initiatives aim to reduce water stress, protect aquatic ecosystems, and expand safe water access, with progress demonstrated through defined metrics and regular monitoring.

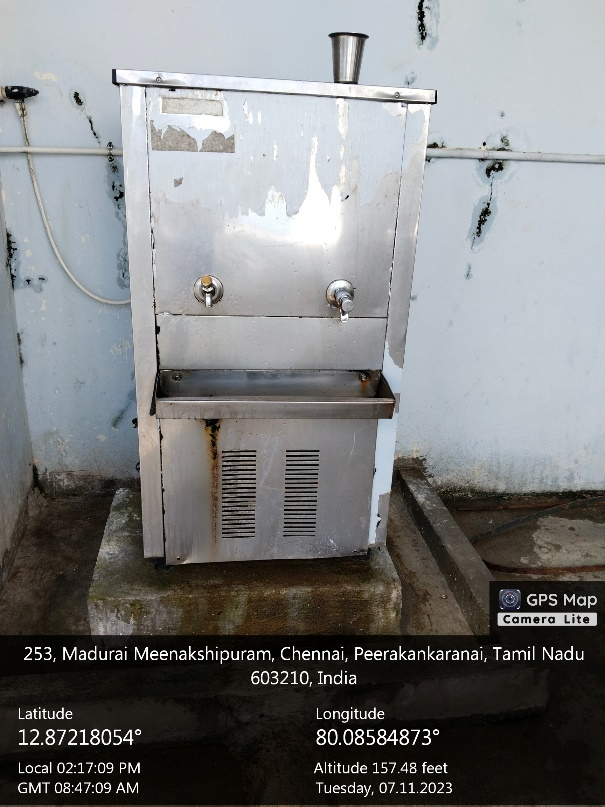

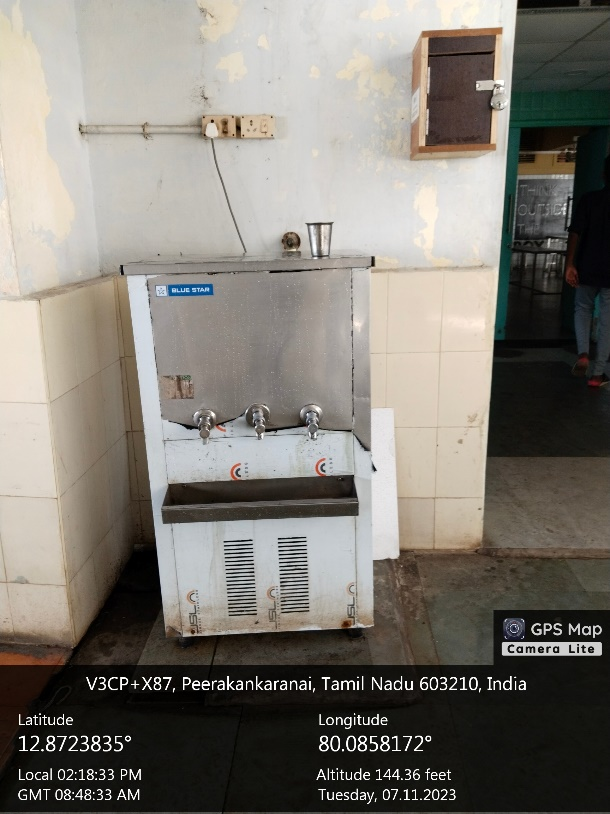

The university actively promotes the availability of free drinking water for students, staff, and visitors by installing drinking water fountains throughout the campus. This initiative is essential for ensuring that all members of the university community have easy access to clean and safe drinking water.

A. MONITORING WATER QUALITY

The university ensures the quality of the drinking water through regular testing and monitoring. Parameters such as microbial content and chemical composition are regularly checked to guarantee safe drinking water for the university community. This proactive quality control is crucial for maintaining health standards and instilling confidence in the available drinking water resources.

B. DISTRIBUTION OF WATER DISPENSERS

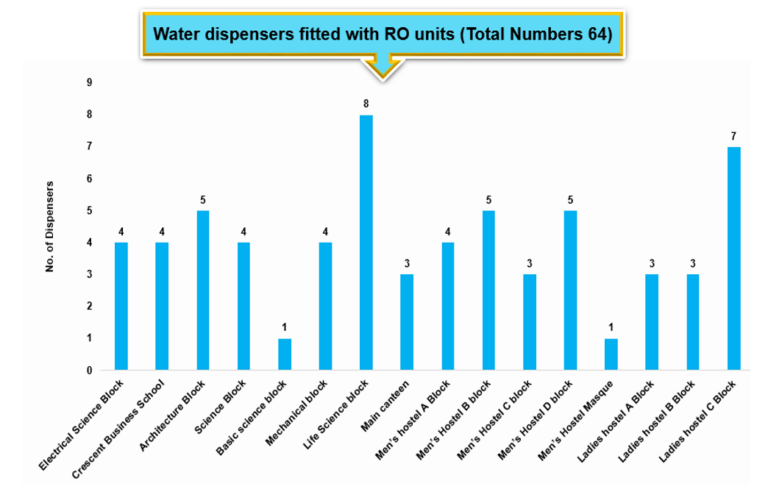

This section summarizes the distribution of water dispensers and RO units across various buildings on campus:

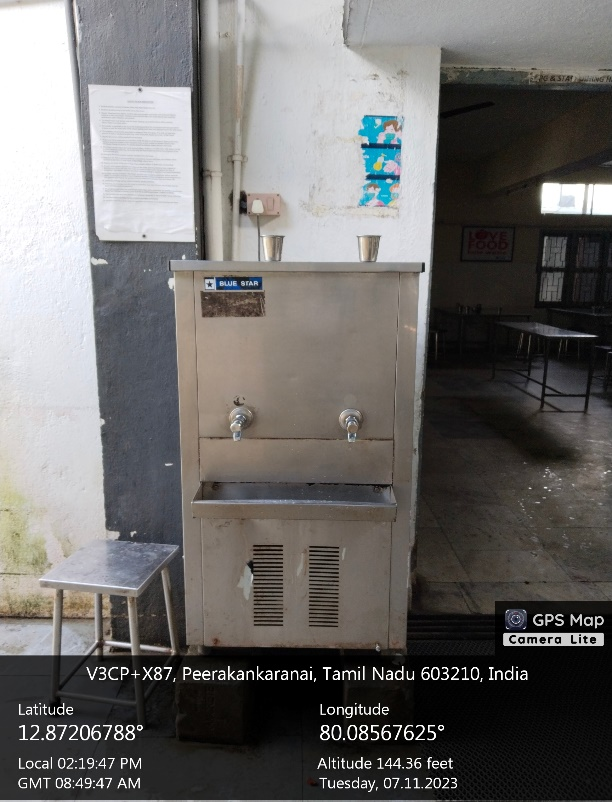

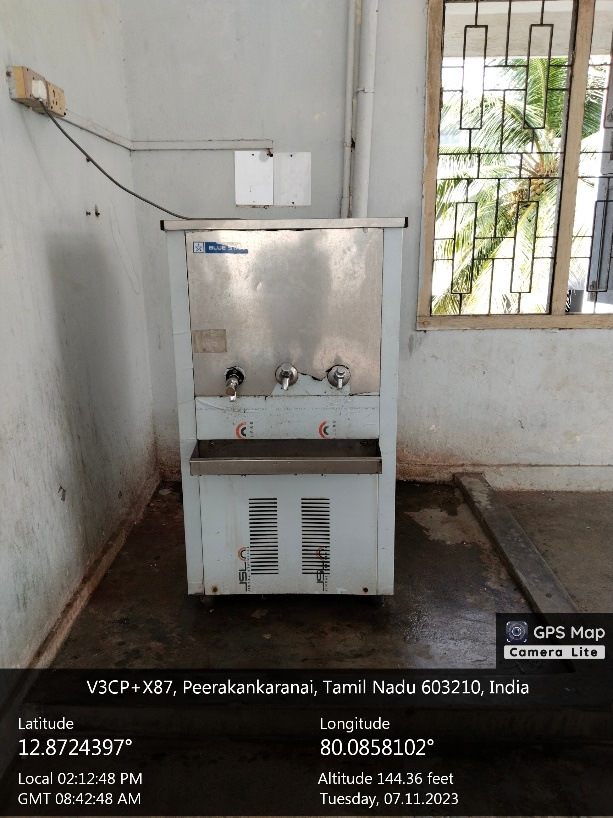

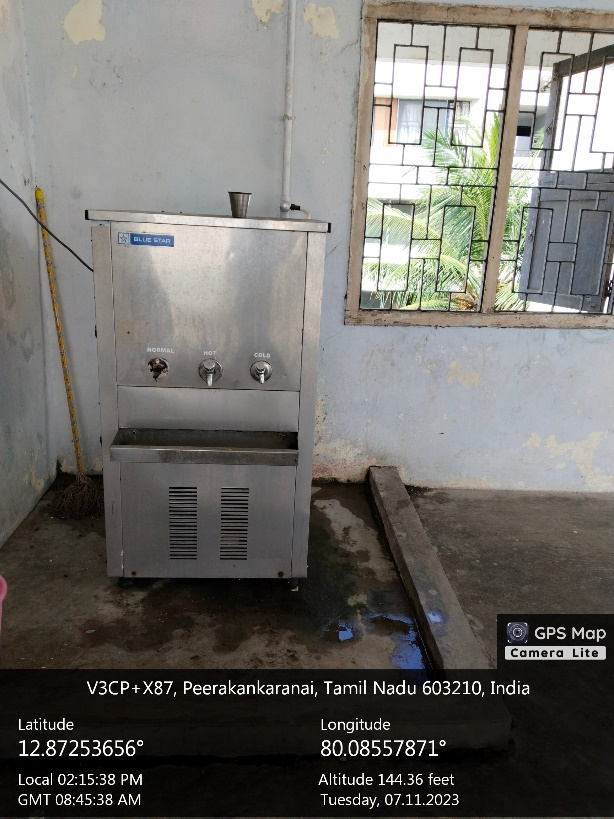

Figure VI (3.3) – 1 depicts a water cooler or dispenser in a men’s hostel, specifically in A Block of the KBA Men’s Hostel in BSACIST.

- Design and Structure: The water cooler has a metallic body with multiple taps for dispensing water. It appears to be mounted on a base, possibly for stability and ease of use.

- Location: The cooler is situated in a common area, likely accessible to residents of the hostel. The surrounding environment includes tiled flooring and walls, indicating a clean and maintained space.

- Details and Conditions: Each image includes GPS coordinates, indicating the exact location of the cooler. The images are timestamped, showing they were taken on October 24, 2025 and November 7, 2023, at various times throughout the day. The cooler appears to be in functional condition, although some areas show signs of wear, such as scratches or marks on the surface.

Figure VI (3.3) – 1: Free Drinking Water dispenser units at different locations

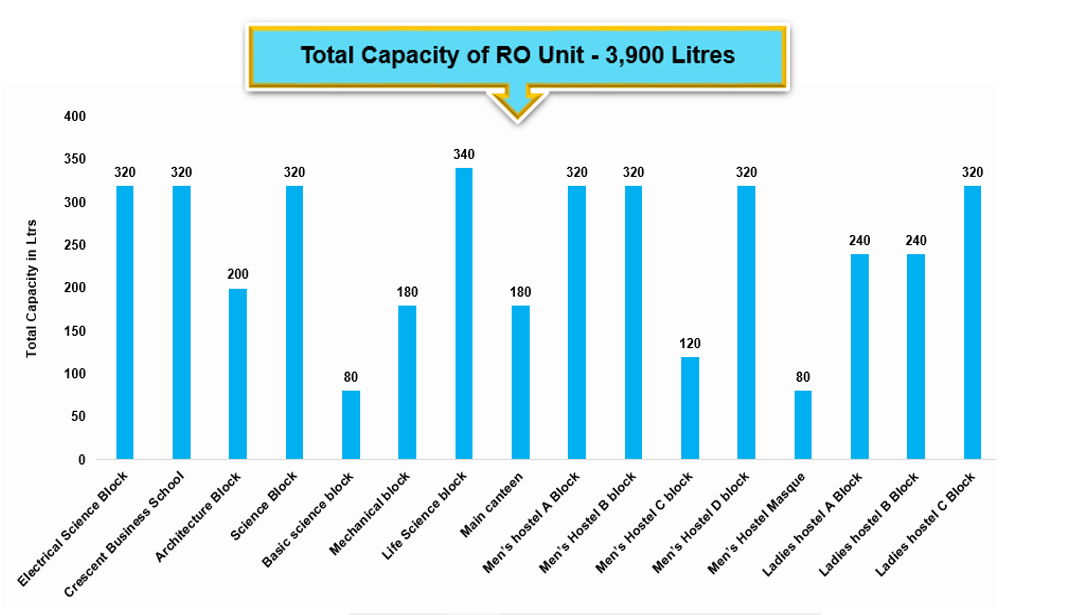

The table VI (3.3) – 1 illustrates that the university has installed a total of 64 water dispensers, each fitted with RO units, across various buildings. The total capacity of these systems amounts to 3,900 litres, ensuring that a significant volume of safe drinking water is available to the campus community.

Table VI (3.3) – 1: Building-wise water dispensers fitted with RO units Data

S.No | Building name | Number of water Dispensers with RO Units | Total capacity |

1 | Electrical Science Block | 4 | 320 |

2 | Crescent Business School | 4 | 320 |

3 | Architecture Block | 5 | 200 |

4 | Science Block | 4 | 320 |

5 | Basic science block | 1 | 80 |

6 | Mechanical block | 4 | 180 |

7 | Life Science block | 8 | 340 |

8 | Main canteen | 3 | 180 |

9 | Men’s hostel A Block | 4 | 320 |

10 | Men’s Hostel B block | 5 | 320 |

11 | Men’s Hostel C block | 3 | 120 |

12 | Men’s Hostel D block | 5 | 320 |

13 | Men’s Hostel Masque | 1 | 80 |

14 | Ladies hostel A Block | 3 | 240 |

15 | Ladies hostel B Block | 3 | 240 |

16 | Ladies hostel C Block | 7 | 320 |

Total | 64 | 3900 | |

Figure VI (3.3) – 2: Building-wise water dispensers

Figure VI (3.3) – 3: Building-wise RO Unit Capacity

The university places a strong emphasis on the maintenance and quality assurance of its water treatment facilities. Regular testing and maintenance of the RO systems ensure that the drinking water provided at every tap meets safety standards. This commitment to quality is essential for safeguarding the health of students, staff, and visitors.

C. RO DRINKING WATER PLANTS

The university has established a network of Reverse Osmosis (RO) plants to supply free drinking water to both the college and hostel facilities. With a total capacity of 13,000 litres per hour and 62,000 litres per day, these systems are designed to meet the hydration needs of the campus community. Water dispensers are strategically located on every floor of each building, ensuring that pure and safe drinking water is readily available at all times.

This table indicates that the total capacity of the RO plants is 13,000 litres per hour, with a total output of 62,000 litres of treated water per day. This extensive capacity ensures that the university can meet the hydration needs of its community effectively.

Table VI (3.3) – 2: RO Plant Capacity

| S. No | Location | Capacity Liters/Hr | Working Hours Per day | Qty. of Treated Water in liters |

| 1 | University Main Plant-Near to Main block | 1500 | 6 | 9000 |

| 2 | Ladies Hostel New block Terrace | 2000 | 4 | 8000 |

| 3 | Men’s Hostel Service block | 4000 | 6 | 24,000 |

| 4 | Aeronautical Block terrace | 1000 | 2 | 2000 |

| 5 | Life Sciences block terrace | 500 | 2 | 1000 |

| 6 | Computer Science Block Terrace | 2000 | 5 | 10,000 |

| 7 | New architecture terrace | 2000 | 4 | 8000 |

| Total treated Water | 13000 | 29 | 62000 | |

The Figure VI (3.3) – 4 depicts various Reverse Osmosis (RO) plants located in different blocks of the hostel and campus. These RO plants are essential for ensuring access to clean and safe drinking water in the respective hostel blocks and in the campus.

- Aeronautical Block RO Plant: This plant features a compact setup with multiple blue tanks, likely for water storage or filtration. It includes a control panel for monitoring and managing the purification process.

- KBA Men’s Hostel RO Plant: This image shows another RO system, possibly similar in function to the Aeronautical Block plant, designed to provide purified water for the men’s hostel.

- Architecture Block RO Plant: This plant has a more extensive arrangement with visible filtration components and a control panel. It appears to be designed for the architecture block, ensuring clean water supply for its occupants.

- TBAK Ladies Hostel New Block Terrace RO Plant: This setup is located on a terrace and includes large storage tanks. It is specifically designated for the ladies’ hostel, indicating a focus on providing safe drinking water for female residents.

Figure VI (3.3) – 4: RO Plant at different locations

D. WATER QUALITY ANALYSIS REPORT

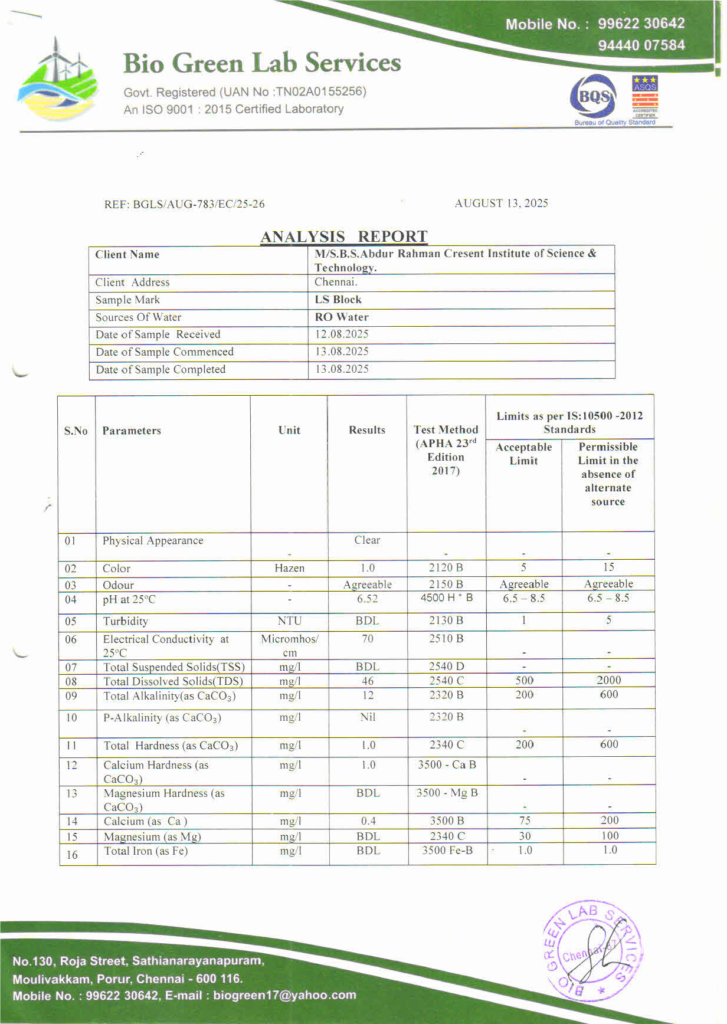

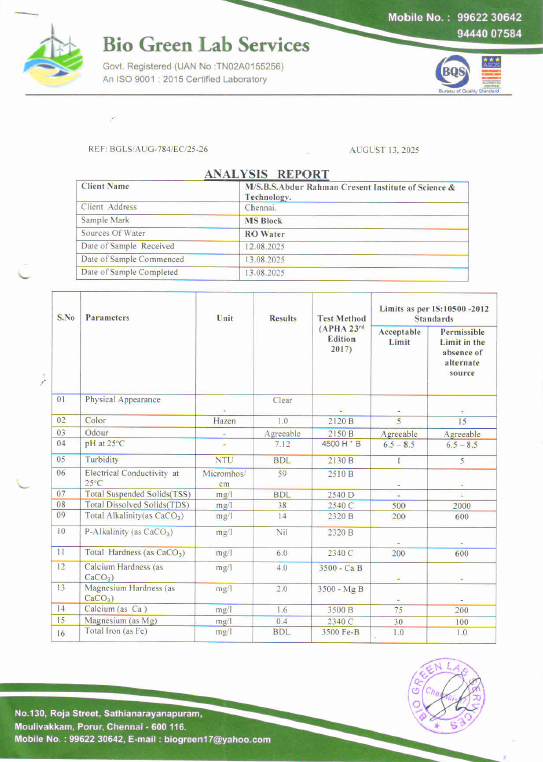

The RO Plant Report comprises multiple water quality analyses conducted by Bio Green Lab Services (Govt Registered, UAN TN02A0155256, ISO 9001:2015) for M/S B.S. Abdur Rahman Crescent Institute of Science & Technology, covering RO water samples from Ladies Hostel, Life Sciences Block, Men’s Hostel, Library, Campus plants, and STP/Treated water contexts.

Results include physical, chemical, and microbiological parameters aligned to IS 10500:2012 (drinking water) standards and APHA methods. Several samples comply, while some show deviations requiring attention, particularly in turbidity, total dissolved solids, alkalinity, hardness fractions, and certain contaminants (chloride, sulfate, silica, oil/grease, COD/BOD in treated outlet).

Figure VI (3.3) – 5: Bio Green Lab Services – Water Audit Report (ISO Certified Company)

SUMMARY OF THE TEST REPORT

Executive summary

- Multiple samples analyzed for drinking water quality and RO plant treated outputs (RO water, plant-2, plant-1, STP treated water, etc.).

- Overall, several samples comply with IS 10500:2012 drinking water standards, while others show partial or full non-compliance (notably residual chlorine, certain hardness parameters, silica, and some metals).

- Microbiology results consistently indicate absence of Total Coliforms and E. coli in most samples (compliance), with a few entries showing absence as per IS 10500 requirements.

- Treated water outlet parameters (pH, TDS, TSS, BOD, COD, oil & grease) show mixed results across outlets; some meet TNPCB limits, others do not.

- Reference and general information

- Laboratory: Bio Green Lab Services (UAN TN02A0155256), ISO 9001:2015 certified.

- Sample sources: RO Water, Well Water, Life Sciences Block, Ladies Hostel, Men’s Hostel, Campus canteen, STP Treated Water, etc.

- Reporting dates span mid-August 2025.

- Agencies/standards cited: IS 10500:2012 (drinking water), APHA 23rd Edition (procedures), TNPCB/tolerances, with some methods per 2017 revision.

- Individual sample results and compliance status

A. RO Water – Ladies Hostel

- pH (25°C): 6.5–6.8 range observed in various entries; IS 10500 acceptable range 6.5–8.5.

- Odour: Agreeable; acceptable.

- Turbidity: Below Detection Limit (BDL) to 0.3 NTU (acceptable: ≤ 5 NTU).

- Conductivity: 70–76.9 µS/cm at 25°C (acceptable: ≤ 2500 µS/cm).

- TDS: 40–1128 mg/L across entries (varies by sample; some entries near or above 600 mg/L limit for drinking water (2000 mg/L max under IS 10500); most entries are below 600 mg/L but one shows 1128 mg/L in “TDS” for a college plant sample outlet; this may be a concern if intended as drinking water; confirm sampling point).

- Total Alkalinity as CaCO3: 12–280 mg/L (within 200–600 mg/L acceptable range varies by sample source; IS 10500 does not set strict limits for T.A. in all contexts; ensure within acceptable range per IS 10500).

- P-Alkalinity: Nil to 6.0 mg/L (Nil or low; acceptable as per IS 10500).

- Total Hardness as CaCO3: 7–14 mg/L (low hardness; acceptable).

- Calcium hardness: 4–8 mg/L; Magnesium hardness: 0–6 mg/L.

- Iron: BD L or below 1.0 mg/L (acceptable).

- Chloride: 13–29 mg/L.

- Sulphate: 4.5–11 mg/L.

- Silica (as SiO2): 1.0–1.2 mg/L.

- Free Residual Chlorine: BDL to 0.2 mg/L; some entries show Nil or BDL (acceptable if residual chlorine target is not critical for the downstream use; for drinking water, residual chlorine is typically desired; confirm local requirement).

- Remarks: Some samples “Comply with drinking water specification” while others “Does Not Comply” (notably entries of 7.0–7.4 pH, high TDS 1128 mg/L, and some residual chlorine non-detection if required). See specific notes per sample.

B. RO Water – Ladies Well Water

- pH: 6.5–7.0 (within IS range).

- Odour: Agreeable.

- Turbidity: BD L to 0.3 NTU.

- TDS: 420–948 mg/L (varies; some samples meet ≤ 600 mg/L recommended for drinking water; others exceed).

- Alkalinity: 12–280 mg/L (as CaCO3).

- Total Hardness: 14–420 mg/L (some samples show 420 mg/L; within IS 10500’s typical hardness guidelines? IS 10500 doesn’t specify a single hard-limit; e.g., 600 mg/L as a general external guidance).

- Calcium: 4.3–114.2 mg/L.

- Magnesium: 0–140 mg/L.

- Iron: BD L–1.0 mg/L.

- Chloride: 16–29 mg/L.

- Sulphate: 7.3–98.5 mg/L.

- Free Residual Chlorine: BD L to 0.0–0.2 mg/L.

C. Microbiology – Ladies Hostel / Life Sciences Block / Other RO plant samples

- Total Coliforms: Absent in all listed entries (compliant with IS 10500:2012).

- E. coli: Absent (compliant).

- Remarks consistently indicate compliance for the tested provisions.

D. Treated Water Outputs (Outlets)

- College Plant (Treated Outlet): pH around 7.6–7.7; TDS 1028–1128 mg/L; TSS BD L; BOD 3.0–3.5 mg/L; COD 17–19 mg/L; Oil & Grease BD L.

-

- TNPCB drinking water limits are not explicitly cited here, but high TDS (1128 mg/L) may exceed typical drinking water recommendations (IS 10500 provides guidance; often aims for <= 1000 mg/L). The BOD/COD values appear reasonable.

- STP Treated Water: pH 7.63–7.71; TDS 1028–1128 mg/L; TSS BD L; BOD 3.0–3.5 mg/L; COD 17–19 mg/L; Oil & Grease BD L.

-

- Non-compliance noted for some samples (the August 16, 2025 report indicates “Not Comply with drinking water specification as per IS:10500:2012” for some parameters). In the “Treated Outlet as per TNPCB” table, pH within range; TDS and other parameters may require monitoring.

E. Campus Canteen / Well Water samples

- Turbidity in canteen/well water samples generally within acceptable limits (BDL to 1.2 NTU).

- TDS ranges 38–898 mg/L depending on the source/outlet; some high values observed (e.g., 898 mg/L).

- Chloride: 13–241 mg/L.

- Sulphate: 4.5–153 mg/L.

- Free Residual Chlorine: BD L to Nil (acceptable in distribution systems where chlorine is not required for non-potable uses; for drinking water, residual chlorine is typically desired).

- Total Iron: 0.1–1.89 mg/L (some samples exceed 1.0 mg/L; IS 10500 allows up to 0.3 mg/L for iron? Actually IS 10500 does not specify a strict mg/L limit for iron; many guidelines cite 0.3 mg/L as a limit for iron in drinking water; however the IS 10500 standard for iron is 0.3 mg/L? The data here uses “1.0” as a test method standard; please verify local limit if needed.)

- Calcium/Magnesium: within typical ranges in most entries, some values show magnesium up to 150 mg/L.

F. PM: STP Treated Water

- pH around 7.63–7.71; TDS around 1028–1128 mg/L; BOD 3.0–3.5 mg/L; COD 17–19 mg/L; Oil & Grease BD L; Silica ~12–15.9 mg/L; Free Chlorine BD L or Nil.

- Observations and potential issues

- TDS variability is significant across samples, with several readings well above 600 mg/L (some up to ~1128 mg/L). IS 10500 allows general use drinking water with TDS values typically acceptable up to around 1000 mg/L, but the precise limit depends on use and local norms. Consider post-treatment polishing or source evaluation if drinking water usage is intended for those higher-TDS samples.

- Free residual chlorine is often BD L or very low. If disinfection residual is required for safety, ensure that chlorination is maintained at recommended levels (commonly 0.2–0.5 mg/L) in distribution points.

- For some samples, Calcium Hardness and Magnesium Hardness values are relatively high (e.g., Calcium hardness 60–110 mg/L in some lines; Magnesium hardness up to 150 mg/L). While not always disqualifying, elevated hardness may affect taste/softness and scaling. Consider water softening if softness is required for specific processes or consumer acceptance.

- Iron levels in some samples are BD L to 1.89 mg/L; if IS 10500 is applied strictly, iron limit is around 0.3 mg/L (check latest local limit). If used for drinking water, consider iron removal (filtration/oxidation) where needed.

- Recommendations

- For drinking water outlets showing higher TDS (e.g., > 1000 mg/L), assess source water quality and consider post-treatment steps such as reverse osmosis polishing, ion exchange, or blending with lower-TDS sources to meet recommended drinking water standards.

- Ensure residual chlorine distribution targets are met for safety, particularly at service taps. Regular monitoring and adjustment of disinfection dosing.

- Implement routine microbiological checks (as already performed) with a frequency aligned to supply reliability and occupancy; maintain zero total coliforms and E. coli per IS 10500.

- Review hardness and mineral balance for processes or consumer preference; if taste/scale is an issue, consider softening or remineralization steps as appropriate.

- Maintain documentation of sampling points and ensure samples are taken consistently at representative points (e.g., post-RO output, distribution taps, well water upstream of treatment, etc.)

REPORT LINKS

- BGLS-AUG-782- Ladies well water-RO Test Report 2025

- BGLS-AUG-783-LS block RO test report 2025

- BGLS-AUG-784-MS block- RO test report 2025

- BGLS-AUG-785 – Ladies Hostel – RO Test Report 2025

- BGLS-AUG-786-Men’s Hostel well water- RO Test report 2025

- BGLS-AUG-788-Men’s Hostel RO Test report 2025

- BGLS-AUG-789- Men’s Hostel – RO Test report 2025

- BGLS-AUG-791-College Plant-RO test report 2025

- BGLS-AUG-792-Campus canteen-RO test report 2025

- BGLS-AUG-793-LIfe Science block RO Test report 2025

Water Management and Reuse Policy

Issue: 04; Revised on 2023

| Policy Created on | July 2009 |

| 1st Revision amended on | IQAC Meeting held on 27th October 2017 |

| 2nd Revision amended on | IQAC Meeting held on 31st March 2021 |

| 3rd Revision amended on | IQAC Meeting held on 16th June 2023 |

Responsible Executive : Director (IQAC)

Responsible Office : Internal Quality Assurance Cell,

Student Affairs, Estate Office, Academic Office, Library and SDG Cell

Contacts : Registrar and Director (IQAC)

6.1 STATEMENT OF POLICY

The B.S. Abdur Rahman Crescent Institute of Science and Technology is committed to achieving the following objectives in alignment with Sustainable Development Goal 6 (SDG 6) – Clean Water and Sanitation:

a) Ensure universal and equitable access to safe and affordable drinking water for all stakeholders.

b) Provide adequate and equitable sanitation and hygiene for all, with special attention to the needs of women, girls, and vulnerable groups.

c) Improve water quality by reducing pollution, eliminating dumping, and minimizing the release of hazardous chemicals and materials.

d) Halve the proportion of untreated wastewater and substantially increase recycling and safe reuse globally.

e) Substantially increase water-use efficiency across all sectors and ensure sustainable withdrawals and freshwater supply to address water scarcity.

f) Implement integrated water resources management at all levels, including transboundary cooperation as appropriate.

g) Protect and restore water-related ecosystems, including mountains, forests, wetlands, rivers, aquifers, and lakes.

h) Expand international cooperation and capacity-building support to developing countries in water- and sanitation-related activities and programs.

i) Support and strengthen the participation of local communities in improving water and sanitation management.

6.2 REASON FOR THIS POLICY

The policy aims to provide all stakeholders with adequate water supply, sanitation, and hygiene. It emphasises maximising the collection and treatment of sewage generated and the reuse of treated wastewater sustainably, thereby reducing dependency on freshwater resources. The policy promotes treating wastewater as an economic resource.

6.3 RESPONSIBILITIES

6.3.1 Policy Principles

a) The campus shall provide adequate water supply and maximize water reuse by adhering to the following principles:

- Equitable access to safe and affordable drinking water for all stakeholders.

- Access to adequate sanitation and hygiene, ending open defecation, with special attention to vulnerable groups.

- Calculation of water usage per person (students, staff, and faculty) annually.

- Improving water quality by reducing pollution and increasing recycling and safe reuse.

- Utilization of recycled/treated wastewater for beneficial purposes, such as irrigation and toilet flushing.

- Implementation of integrated water resources management at all levels.

- Protection and restoration of water-related ecosystems on campus.

- Expansion of rainwater harvesting initiatives.

- Collaboration with government, NGOs, and industries in water-related activities.

- Support for student and staff participation in water management.

6.4.1 Water Reuse Policy Objectives

- Establish a comprehensive policy to maximize water reuse across the university.

- Ensure that all new buildings adhere to water-conscious building standards that facilitate water reuse.

- Implement systems for tracking and measuring water consumption and reuse.

6.4.2 Water Reuse

- Water Reuse Policy: maximise water reuse across the university.

- Water Reuse Measurement: Measure water reuse across the university.

6.5 DISSEMINATION OF POLICY

a) Display signage promoting water use efficiency across the campus.

b) Conduct awareness programs at regular intervals to increase water-use efficiency.

c) Post the policy on the Institute’s website and update it as necessary.

6.6 ENFORCEMENT OF POLICY

a) The Director (Planning & Development) and Deputy Director monitor compliance and address breaches.

b) Awareness of the policy among students, staff, and visitors is essential.

c) Breaches may lead to disciplinary action as per the Institute’s code of conduct.